A Parkside quartet.

The Airfix meat van I did a short while ago has peaked my interest just a smidge. There is a little bit of local interest for this (or a well sketchy excuse for me to go waffling on for a minute or two!).

The Airfix meat van I did a short while ago has peaked my interest just a smidge. There is a little bit of local interest for this (or a well sketchy excuse for me to go waffling on for a minute or two!).

Meat products moved by rail were probably most famous for the Palethorpes vans that operated out of the Dudley area but Brierley Hill was also famous for another processed meat producer, Marsh and Baxter. Founder, Alfred Marsh brought a pork butchers shop (with slaughter house) from E.J. Smart on Brierley Hill High Street in 1867 and initially started out curing ham and manufacturing sausages. By 1912 he brought the A.R Baxter factory in Dale End, Birmingham. Alfred Marsh died in 1918 and the business passed to his son Alfred Edward Marsh. After WW1 the company continued absorbing smaller firms and was eventually granted a Royal Warrant for its York Hams, which they supplied to Harrods.

In 1927 They began using their own siding at Brierley Hill Station and at their peak employed some 1500 workers and slaughtering approximately 2000 pigs per day. It was quite famous locally for an advert featuring a pig pulling a trailer loaded with sausages and the strap line ‘Drawing his on conclusion’. In 1954 a modern office building was built on Church Street, Brierley Hill which being slighter higher than the Round Oak steel works did tend to dominate the town somewhat. They also took a keen interest in investing in and promoting local sports and social interests and had both a cricket and football teams (both mens and womens).

In 1962 the company was brought out by Falstock Marketing Corporation although the Marsh and Baxter name was retained. It would survive another 16 years until December 1978 when the company was closed.

This one is a Diagram 1/250 example using Airfix ends kindly supplied by my friend Ian. Knowing what I know now it would have been better to use a parkside standard 12t van as the meat van has different doors. Luckily I still had some suitable doors in my spares box. The ens needed chamfering to 45 degrees to match the ends and the floor needed shortening a little as the Airfix ends are thicker. I also used some spare underframe mouldings to get the BR welded plate fronted axle boxes.

This one is a Diagram 1/250 example using Airfix ends kindly supplied by my friend Ian. Knowing what I know now it would have been better to use a parkside standard 12t van as the meat van has different doors. Luckily I still had some suitable doors in my spares box. The ens needed chamfering to 45 degrees to match the ends and the floor needed shortening a little as the Airfix ends are thicker. I also used some spare underframe mouldings to get the BR welded plate fronted axle boxes. On the subject of vans I quite like these ex GWR mink Gs. Another Parkside kit with Bill Bedford springing and some other etched bits and bobs to refine the underframe a little.

On the subject of vans I quite like these ex GWR mink Gs. Another Parkside kit with Bill Bedford springing and some other etched bits and bobs to refine the underframe a little. Moving on to Parkside’s latest effort. The BR 13t hopper. You can feel the Peco in this one! The underframe has similar feel (both in the way it’s done and the plastic its done in) to the old wonderful wagons tank kits. I needed to get the scalpel out to get it to fit together the way it was intended but once done it does result in a pretty solid chassis. I don’t know what happened with the supplied axleboxes but they seemed unfinished to me, almost as if there should have been an overlay as per the palvan kit. As there wasn’t I cut them off completely and replaced them with Wizard Models castings.

Moving on to Parkside’s latest effort. The BR 13t hopper. You can feel the Peco in this one! The underframe has similar feel (both in the way it’s done and the plastic its done in) to the old wonderful wagons tank kits. I needed to get the scalpel out to get it to fit together the way it was intended but once done it does result in a pretty solid chassis. I don’t know what happened with the supplied axleboxes but they seemed unfinished to me, almost as if there should have been an overlay as per the palvan kit. As there wasn’t I cut them off completely and replaced them with Wizard Models castings. Knowing what to look out for it does build into a nice looking wagon and its pretty quick to bung one together. The model features some nice moulding on both sides of the hopper doors but with no where to really put any decent amount of weight I suspect many (like i will) will run them loaded.

Knowing what to look out for it does build into a nice looking wagon and its pretty quick to bung one together. The model features some nice moulding on both sides of the hopper doors but with no where to really put any decent amount of weight I suspect many (like i will) will run them loaded. The inevitable comparison with my previous model from the Dave Bradwell kit. Draw your own conclusions.

The inevitable comparison with my previous model from the Dave Bradwell kit. Draw your own conclusions.Another classic

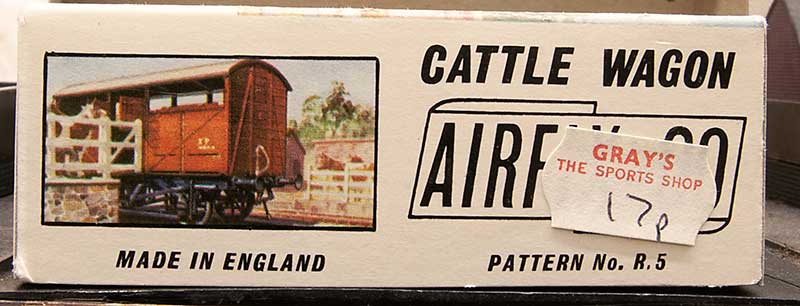

The good old Airfix cattle van. When I was a kid my dad built one of these so I decided Brettell lane should probably have one too. I deleted the opening doors (it was easier to replace the top ones completely than modify what was in the kit) and detailed the underframe with Mainly Trains, Bill Bedford and Rumney models parts.

The good old Airfix cattle van. When I was a kid my dad built one of these so I decided Brettell lane should probably have one too. I deleted the opening doors (it was easier to replace the top ones completely than modify what was in the kit) and detailed the underframe with Mainly Trains, Bill Bedford and Rumney models parts.

As with all Airfix kits of the time the roof was pretty clunky so that was replaced with a new one from 30thou plasticard and microstrip.

As with all Airfix kits of the time the roof was pretty clunky so that was replaced with a new one from 30thou plasticard and microstrip.

Ive no idea when this kit was first sold but even with modern eyes this looks like it was bit of a bargain!

Ive no idea when this kit was first sold but even with modern eyes this looks like it was bit of a bargain!

Moving on to a more recent kit. The Chivers model for an LMS long low thats been in my stash for a few years now.

Moving on to a more recent kit. The Chivers model for an LMS long low thats been in my stash for a few years now.

Also from Chivers, and also from my stash, I’ve finished off another LMS twin bolster. Chivers kits seem to have quite chunky underframe mouldings and while this isn’t noticeable on most of their kits I’ve built it was kind of more obvious on the first twin bolster I built (on the left). Potentially the use of sprung suspension adding to the problem I felt the underframe looked too wide and the w irons were too far from the wheels, giving a kind of 00 look to the wagon. On the new one (and the long low pictured above) I thinned the w irons to about half thickness and I’m happier now. It might very well that its only something I notice though!

Also from Chivers, and also from my stash, I’ve finished off another LMS twin bolster. Chivers kits seem to have quite chunky underframe mouldings and while this isn’t noticeable on most of their kits I’ve built it was kind of more obvious on the first twin bolster I built (on the left). Potentially the use of sprung suspension adding to the problem I felt the underframe looked too wide and the w irons were too far from the wheels, giving a kind of 00 look to the wagon. On the new one (and the long low pictured above) I thinned the w irons to about half thickness and I’m happier now. It might very well that its only something I notice though!

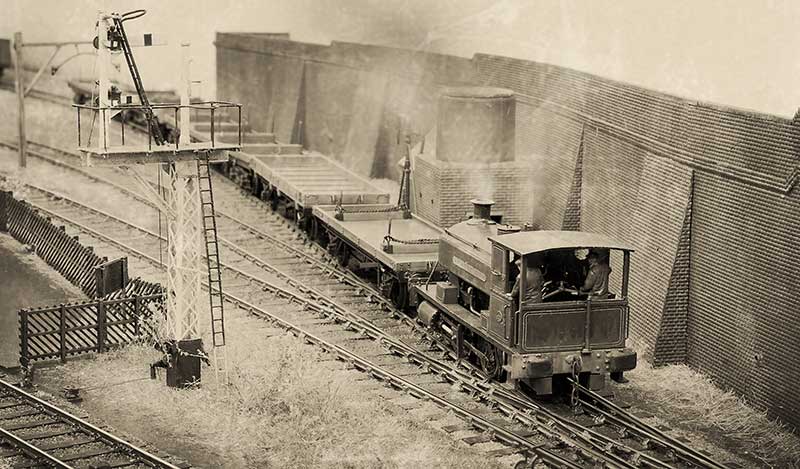

A ‘historic’ photo of the Barclay tank shuffling a steel train.

A ‘historic’ photo of the Barclay tank shuffling a steel train.

A couple of stragglers

Pictured above is a Cooper Craft kit for a GWR diagram 02 open wagon. I found that if you use the bearing holes supplied in the kit the wagon sits too high so the holes were enlarged vertically a bit at a time, checking the wagon on a bit of glass to ensure all 4 wheels stayed square. The rail is a modified Rumney models kit and the brake gear from MRD.

Pictured above is a Cooper Craft kit for a GWR diagram 02 open wagon. I found that if you use the bearing holes supplied in the kit the wagon sits too high so the holes were enlarged vertically a bit at a time, checking the wagon on a bit of glass to ensure all 4 wheels stayed square. The rail is a modified Rumney models kit and the brake gear from MRD.

The infamous Airfix meat van. Quite why Airfix picked this and not a standard 12 ton van is anyones guess. I replaced the gimmicky opening doors and the underframe with Parkside bits from my spares box. The transfers were cobbled together from what I had and those that were white were painted with revel clear yellow (730). Buffers on this and the GWR open were from Accurascale. Basically cheap and cheerful!

The infamous Airfix meat van. Quite why Airfix picked this and not a standard 12 ton van is anyones guess. I replaced the gimmicky opening doors and the underframe with Parkside bits from my spares box. The transfers were cobbled together from what I had and those that were white were painted with revel clear yellow (730). Buffers on this and the GWR open were from Accurascale. Basically cheap and cheerful!

A private railway favourite and an exhibition last hour staple, the good old brake van special! I think i might have overdone it a bit!

A private railway favourite and an exhibition last hour staple, the good old brake van special! I think i might have overdone it a bit!

Bit of pick ‘n’ mix

Bit of a pick ‘n’ mix post this one.

Lady Margaret now has her identity thanks to some custom nameplates from Narrow Planet

Lady Margaret now has her identity thanks to some custom nameplates from Narrow Planet

Finding your own compromise

When it comes to plastic kit building it helps if you think of a line. At one end of the line you have the kit as supplied, built as per the instructions with no attention or research what so ever on the prototype itself. At the other end you have the kit, researched, wrong parts replaced or corrected and superior parts substituted, as much extra detail as you can manage. Rumney chassis kind of thing. Inevitably we all need to find our place somewhere along the line that we feel comfortable.

This place can be influenced by several factors.

Cost – adding a lot of extra parts can mount up to quite an expensive model.

Expediency – high end models take a lot longer to build. Do we have the time

Reliability – no point adding every little detail if in use you’re going to knock it all off again.

Usage – if you wagon is part of a train of 30 that are only ever going to trundle past at a scale 40mph are you going to have the opportunity to notice the extra work?

Consistency – no point mixing highly detailed and basic kit builds together really.

Volume – how many models are we going to need?

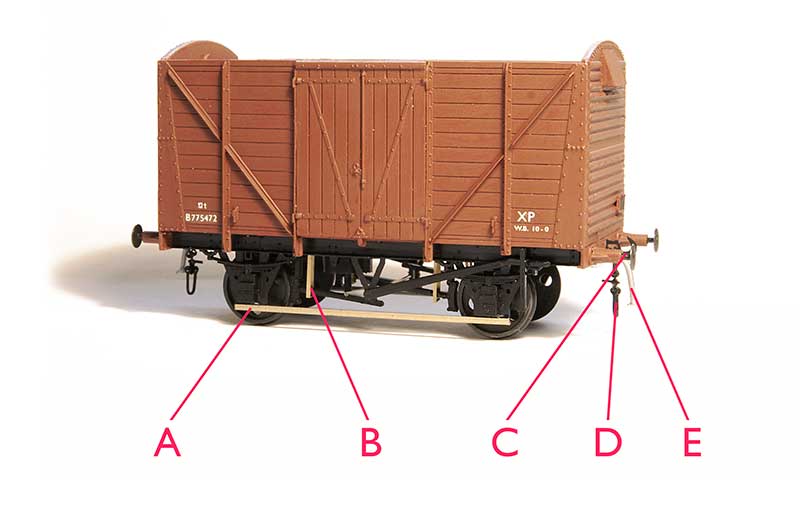

Heres my pretty much standard position along that line. The base model is a parkside kit. As mentioned elsewhere I’m not particularly worried about compensation or springing on a 10ft wheelbase wagon but i do use it for vehicles longer than 12ft wb.

Heres my pretty much standard position along that line. The base model is a parkside kit. As mentioned elsewhere I’m not particularly worried about compensation or springing on a 10ft wheelbase wagon but i do use it for vehicles longer than 12ft wb.

A – brass tie bars. I use 0.8mm L section. the real things aren’t L section but i use this for strength and you cant tell unless you turn the model upside down. In plastic kits the tie bars are a real weakness ad they are either bendy, get broken or to avoid those 2 things, massively thick.

B – break hangers from Bill Bedford – It doesnt take much to add a little finesse to the brake gear and trick the mind into thinking its all a bit more refined that it actually is.

C – metal buffers, or in this case metal buffer heads. Unless your kit comes with metal buffers already lets be honest here, the plastic ones are going to be awful. These are MJT buffer heads.

D – couplings. A whole discussion on compromises in itself. In my case I use Smiths which i know are overscale but they are (quite) easy to use in operation.

E – brake pipe from Lanarkshire models.

Glue

Ive recently been trying this stuff. Ultra Glue from MIG for etched and clear parts. Its water based so can be thinned if required and so far it seems to do the job at least as well as superglue. Its especially good for fitting name plates as while it has good grab it takes a few hours to fully harden and being water base any that creeps out can be lifted off with a wet paintbrush.

Ive recently been trying this stuff. Ultra Glue from MIG for etched and clear parts. Its water based so can be thinned if required and so far it seems to do the job at least as well as superglue. Its especially good for fitting name plates as while it has good grab it takes a few hours to fully harden and being water base any that creeps out can be lifted off with a wet paintbrush.

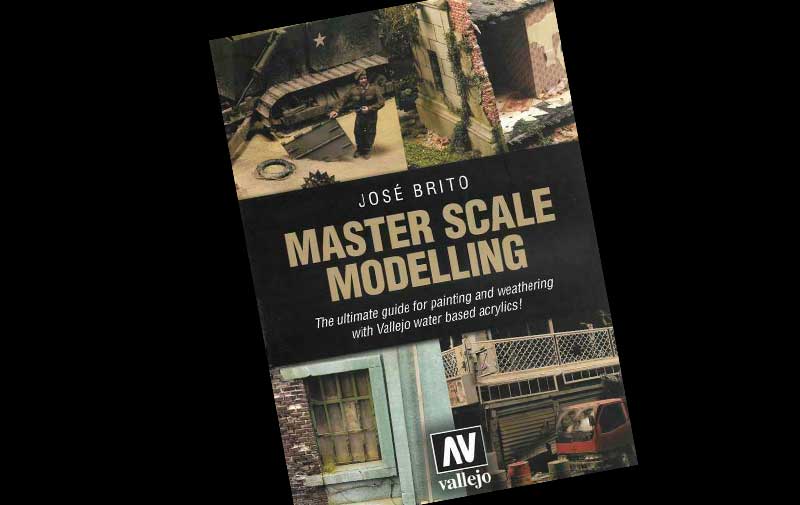

Reading

It’s been an awful long time since Martin Welch treated us to his ‘bible’ the art of weathering. And while still essential reading things have moved on a bit, especially so in the last few years or so. Some of the paints Martin used are no longer available (Humbrol tarmac for example) but theres a whole market now of weathering paints and materials. This (rather large at over 500 pages) book is an excellent window outside of our sometimes a little comfortable railway world.

Having had a little trundle to Stourbridge shed and back for some Diesel, Class 11 shunter 12049 waits for the nod back into the yard at Brettell Road.

Years end – more fiddly bits

As 2021 draws to an end I’ve been doing some of those fiddly little jobs that I kind of hope always get lost into the scene but I know they are there.  Starting with a pushbike from the Southwark Bridge Models Kit. The kit is for a late 19th century bike so I modernised it a little. I think these may be reduced from 7mm scale model as some of the parts are at the very limit of what will etch and gives you a decent idea of what it must be like to try and solder a spiders web together!

Starting with a pushbike from the Southwark Bridge Models Kit. The kit is for a late 19th century bike so I modernised it a little. I think these may be reduced from 7mm scale model as some of the parts are at the very limit of what will etch and gives you a decent idea of what it must be like to try and solder a spiders web together!

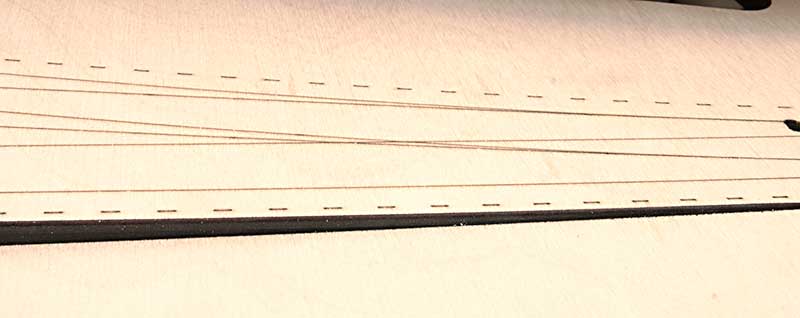

I’ve finished off the signal wires using MSE posts and easyline.

I’ve finished off the signal wires using MSE posts and easyline.

This meant I could finally get the barrow crossing finished too.

This meant I could finally get the barrow crossing finished too.

Below are a few evening shots of various comings and goings.

Below are a few evening shots of various comings and goings.

Hattons Barclay Tank Part 2

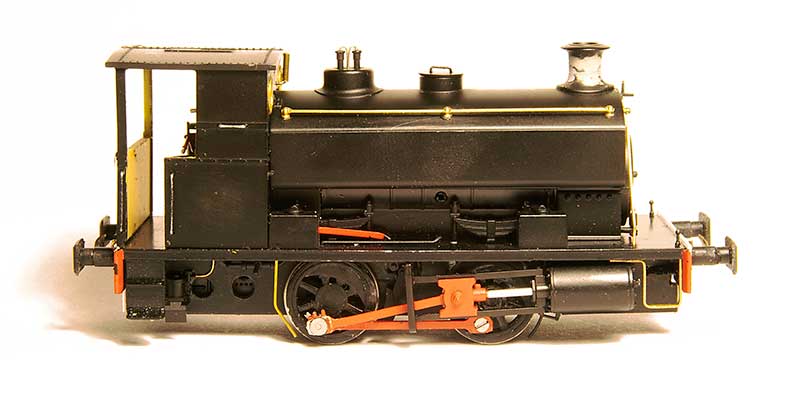

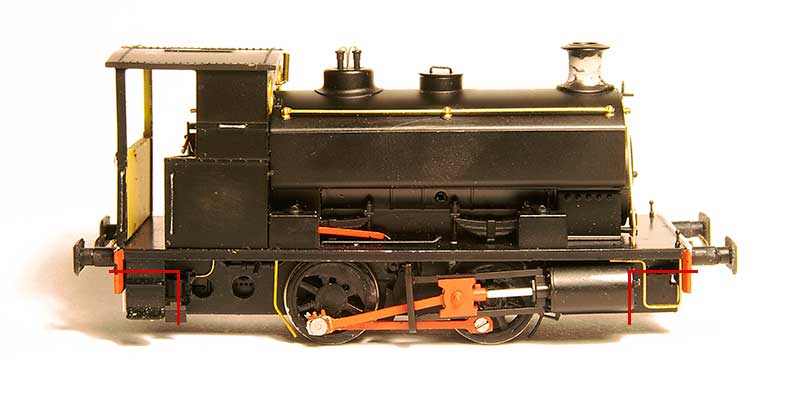

One change since the last post on this little tank is I’ve replaced the tantalum capacitors with a Lais stay alive unit on the recommendation of Nigel Cliffe. With this little motor I’ve now got about 4-5 seconds of off the juice running which is a big improvement.

The model has been finished and lined with Fox transfers lining. I just need the number plate and name which is on order with Narrow Planet. I decided to take a quick shot of it for prosperity before i covered it all in goo!

The model has been finished and lined with Fox transfers lining. I just need the number plate and name which is on order with Narrow Planet. I decided to take a quick shot of it for prosperity before i covered it all in goo!

And post goo!

And post goo!

The crew are, the almost customary now, Modelu Figures

The crew are, the almost customary now, Modelu Figures

I used to think my Deeley was tiny!

I used to think my Deeley was tiny!

A dash of autumnal weather.

After much experimentation on Brettell Road part 1 and coming up with a working formula. Adding rain to part 2 was a much simpler process (although still a bugger to photograph mind you!)

View from the middle looking towards Stourbridge. The method I have settled on is to spray everything that needs to be wet with a fine coat of Tamiya smoke. When dry a coat of AK interactive wet effect is added and thats really it. Simple enough now but it took an awful lot of faffing about to get here!

View from the middle looking towards Stourbridge. The method I have settled on is to spray everything that needs to be wet with a fine coat of Tamiya smoke. When dry a coat of AK interactive wet effect is added and thats really it. Simple enough now but it took an awful lot of faffing about to get here!

View towards Dudley

View towards Dudley

This is the view from the old layout to the new one . While its not something I intended to capture when I took the picture it does show the elevation changes quite well.

This is the view from the old layout to the new one . While its not something I intended to capture when I took the picture it does show the elevation changes quite well.

Below a few evening pictures

Signals

I think I may have mentioned before but one of my favourite things on Moor Street is the mechanical signals. Obviously on New Street there was never going to be an opportunity to do any but on Brettell Road things were different. I had already built a few ground signals on part 1 and an abandoned one but part 2 has given me the opportunity to do some proper, working ones.

So starting with the post for the simple one. Basically a bog standard upper quadrant affair only complicated by the need to have a co-acting signal due to where the signal stands in relation to the footbridge. The balance weights are below the platforms surface. The parts used are the MSE upper quadrant signal parts (S0012/1), LMS/LNER tubular post caps (SC0019) and LMS Adlake signal lamps (SC0011). The Ladder is from Stenson models and various diameters of tube, sized from the left overs from the signal I built before. This will sit at the Stourbridge end of the platform.

So starting with the post for the simple one. Basically a bog standard upper quadrant affair only complicated by the need to have a co-acting signal due to where the signal stands in relation to the footbridge. The balance weights are below the platforms surface. The parts used are the MSE upper quadrant signal parts (S0012/1), LMS/LNER tubular post caps (SC0019) and LMS Adlake signal lamps (SC0011). The Ladder is from Stenson models and various diameters of tube, sized from the left overs from the signal I built before. This will sit at the Stourbridge end of the platform.

At the Dudley end things are a little more entertaining. So having found a suitable victim (which turned out to be a bit of a mongrel) I set to work emulating what I could see. More MSE bits such as Heavy Lattice Bracket Signal Base Post (S0010) and LMS welded stem bracket (50029) for the platform. The rockers came from the Brassmasters point rodding etch. After I took this photo I decided that the operating ‘wires’ were too big so they have been replaced with no8 guitar strings.

At the Dudley end things are a little more entertaining. So having found a suitable victim (which turned out to be a bit of a mongrel) I set to work emulating what I could see. More MSE bits such as Heavy Lattice Bracket Signal Base Post (S0010) and LMS welded stem bracket (50029) for the platform. The rockers came from the Brassmasters point rodding etch. After I took this photo I decided that the operating ‘wires’ were too big so they have been replaced with no8 guitar strings.

Platform starter in position.

Platform starter in position.

Gantry in position. The left arm was used for the Kingswinford branch (now disconnected)

Ticking more things off.

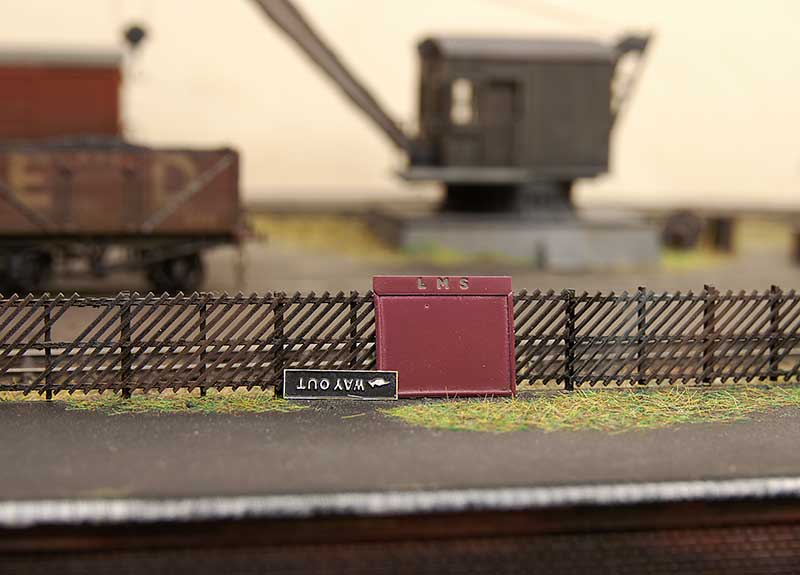

In order to ‘plant’ my abandoned crossing box I needed a base so opportunity was taken to do a micro diorama and take a piccie first. This is the side no one will ever see so it was worth recording for posterity.

In order to ‘plant’ my abandoned crossing box I needed a base so opportunity was taken to do a micro diorama and take a piccie first. This is the side no one will ever see so it was worth recording for posterity.

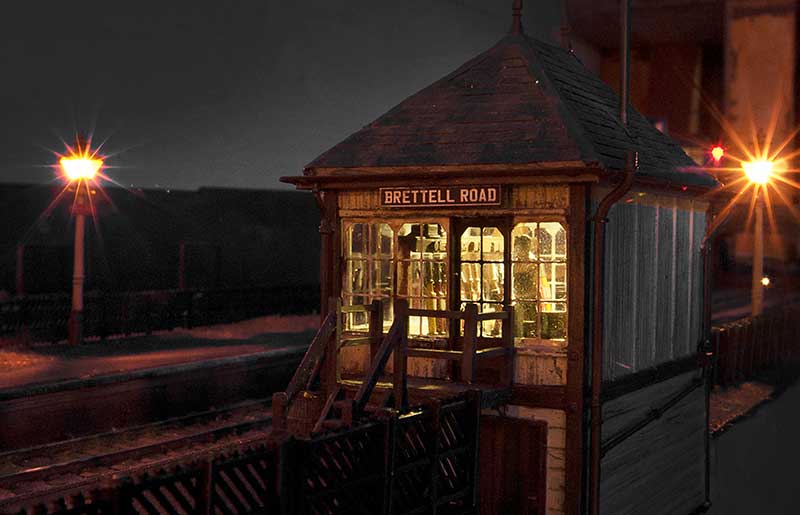

Here’s were it goes on the layout. One of those little out of the way areas that viewers will need to search out a little. The fence is Knightwing modified to resemble pictures of the real place in the late 50s. Below is the low light version.

Here’s were it goes on the layout. One of those little out of the way areas that viewers will need to search out a little. The fence is Knightwing modified to resemble pictures of the real place in the late 50s. Below is the low light version.

Ive also finished off my footbridge. In keeping with the rest of the layout (in fact in keeping with everything I do!) it’s modelled to look tired.

Ive also finished off my footbridge. In keeping with the rest of the layout (in fact in keeping with everything I do!) it’s modelled to look tired.

In an effort to keep the line open to passengers a 4 new fangled 4 wheel railbus was tried on the route. The experiment didn’t work out and the station would be closed a few weeks later.

In an effort to keep the line open to passengers a 4 new fangled 4 wheel railbus was tried on the route. The experiment didn’t work out and the station would be closed a few weeks later.

I’ve mentioned before my preference for long platforms and short trains. A BRCW type 2 and its 3 coaches demonstrates the effect I was after.

I’ve mentioned before my preference for long platforms and short trains. A BRCW type 2 and its 3 coaches demonstrates the effect I was after.

Little bits of abandonment

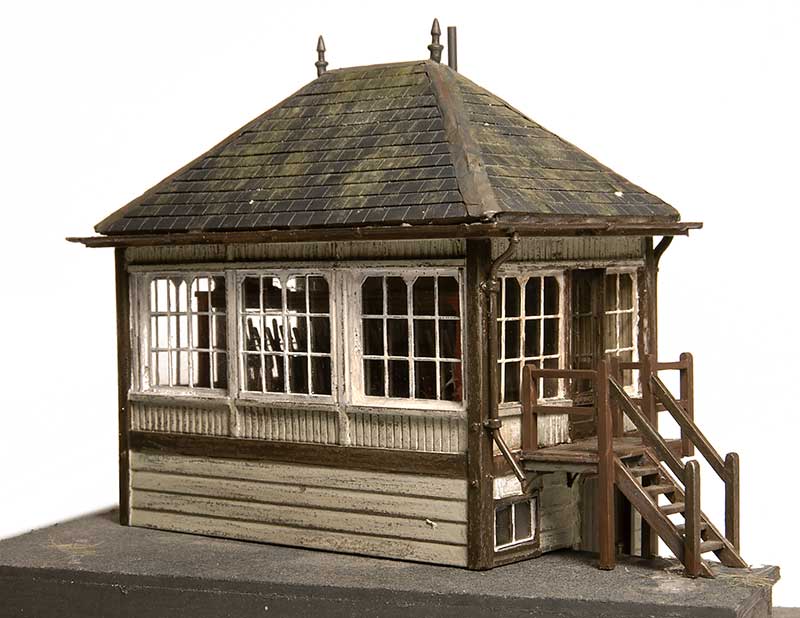

This is a little model of the crossing box from Level Street, modelled in its abandoned state. Ive taken a bit of artistic licence with this as the real building appeared after the layout is set and lasted into the early 1980s. Round oak did tend to move and rebuild things a lot though so a building that became redundant whilst still relatively new wouldn’t have been that unusual for the area. Plus as anyone who’s ever researched a real place will know, not everything at a location will always make a lot of sense. The model is scratch-built with the nifty alarm bell a 3d print kindly supplied by Richard of Mudmagnet Models.

This is a little model of the crossing box from Level Street, modelled in its abandoned state. Ive taken a bit of artistic licence with this as the real building appeared after the layout is set and lasted into the early 1980s. Round oak did tend to move and rebuild things a lot though so a building that became redundant whilst still relatively new wouldn’t have been that unusual for the area. Plus as anyone who’s ever researched a real place will know, not everything at a location will always make a lot of sense. The model is scratch-built with the nifty alarm bell a 3d print kindly supplied by Richard of Mudmagnet Models.

A few bits dumped agains the platform fence give just a hint that the station doesn’t have long left.

A few bits dumped agains the platform fence give just a hint that the station doesn’t have long left.

When I rebuilt my loading gauge (a while ago now) I actually built another one at the same time. The frame is scratch-built from brass sections and the bow from Smiths. This actually serves a purpose as provided the layout is properly levelled this is the point where a free rolling wagon will start to move as the siding descends to the same level as the mainline.

When I rebuilt my loading gauge (a while ago now) I actually built another one at the same time. The frame is scratch-built from brass sections and the bow from Smiths. This actually serves a purpose as provided the layout is properly levelled this is the point where a free rolling wagon will start to move as the siding descends to the same level as the mainline.

Elements of a rudimentary water tower. The prototype for this stood on the Earl of Dudley’s railway at the link between Oak Lane and Stallings Lane, Near to Himley’s No.8 pit. It survived until 1950. Its Heath Robinson look appealed to me.

Elements of a rudimentary water tower. The prototype for this stood on the Earl of Dudley’s railway at the link between Oak Lane and Stallings Lane, Near to Himley’s No.8 pit. It survived until 1950. Its Heath Robinson look appealed to me.

In position on the layout. Its days of servicing the EoD fleet of 0-4-0 saddle tanks are long gone.

In position on the layout. Its days of servicing the EoD fleet of 0-4-0 saddle tanks are long gone.

A short post in brass

Been fiddling with bits of brass again. I wouldn’t normally bother taking a picture of something as simple as a point lever but I found that the ones I built before were a little vulnerable and easily bent. I haven’t changed the ones i use (Shirescenes) but what I have done is doubled up the levers themselves and they now seem a lot more robust.

Been fiddling with bits of brass again. I wouldn’t normally bother taking a picture of something as simple as a point lever but I found that the ones I built before were a little vulnerable and easily bent. I haven’t changed the ones i use (Shirescenes) but what I have done is doubled up the levers themselves and they now seem a lot more robust.

I’ve built platform trollies before to but this time I have changed the supplier. I think my previous ones were Scalelink but this one is from London Road Models and is much more detailed. It even had a representation of the brake linkages. Regular readers will no doubt know by now I’m a sucker for this sort of thing! The trolly is shown perched on a two pence piece for scale.

Moving on to something a little more obvious. This is the Churchward models (now sold by Phoenix models) footbridge kit shown in temporary position. As my track spacing is quite wide here I did need to extend the main arch by one panel and, luckily as the etches for the arch are the same, I could use the spare bits that weren’t needed on the facing side. The sides were cut and shut with the new panels grafted in meaning the only bit I needed to fabricate from scratch was the main span floor. An enjoyable kit to build this one.

Moving on to something a little more obvious. This is the Churchward models (now sold by Phoenix models) footbridge kit shown in temporary position. As my track spacing is quite wide here I did need to extend the main arch by one panel and, luckily as the etches for the arch are the same, I could use the spare bits that weren’t needed on the facing side. The sides were cut and shut with the new panels grafted in meaning the only bit I needed to fabricate from scratch was the main span floor. An enjoyable kit to build this one.

Revisions and clutter

Remember the diagram 1973 mineral wagon I posted a few entries ago? Turns out I missed some of the reinforcing bits that were added after they were built. Im not sure how as they were in the prototype pictures I was looking at! Anyway thats been corrected now

Ive finished off a few Bachmann RTR wagons too.

Ive finished off a few Bachmann RTR wagons too.

The steel high-fit was actually already done. Ive just added a container to it. The other 2 are actually 2 of the 3 vans I first brought for the layout. Discounted in Modellers Mecca bargain bin! The tarpaulin is black latex cut from a surgical glove.

The steel high-fit was actually already done. Ive just added a container to it. The other 2 are actually 2 of the 3 vans I first brought for the layout. Discounted in Modellers Mecca bargain bin! The tarpaulin is black latex cut from a surgical glove.

When I built the retaining wall for this side of the bridge I did intend to do something a little more substantial but decided that It would look weird if the wall was 2 different designs. However a friend mentioned that the buttresses looked a little too puny so I reverted to what i should have done originally and modified the existing wall to match. I admit I did want something more grandiose than this but for where it is it wouldn’t have made a lot of sense to have something to elaborate. I definitely don’t subscribe to that inane ‘rule 1’ idea of its your layout do what you want. There has to be some degree of plausibility in there somewhere.

When I built the retaining wall for this side of the bridge I did intend to do something a little more substantial but decided that It would look weird if the wall was 2 different designs. However a friend mentioned that the buttresses looked a little too puny so I reverted to what i should have done originally and modified the existing wall to match. I admit I did want something more grandiose than this but for where it is it wouldn’t have made a lot of sense to have something to elaborate. I definitely don’t subscribe to that inane ‘rule 1’ idea of its your layout do what you want. There has to be some degree of plausibility in there somewhere.

Clutter – What is a yard if it doesn’t have some clutter in it? Much like the retaining walls though you don’t want to go too mad. At the end of the day this is someones product and they aren’t all that likely to leave it lying around on the floor.

So I opted for 3 small groups of stuff as can be seen above.

So I opted for 3 small groups of stuff as can be seen above.

I always wanted some coal facility and I had this in mind when I built my tractor. Again nothing too posh, no coal staithes or anything like that – just a few piles and some more clutter. The steps, scales and the conveyor (behind the tractor) are 3D prints kindly donated by my friend John.

I always wanted some coal facility and I had this in mind when I built my tractor. Again nothing too posh, no coal staithes or anything like that – just a few piles and some more clutter. The steps, scales and the conveyor (behind the tractor) are 3D prints kindly donated by my friend John.

Finally a couple more evening shots.

Signs of life

With the Stourbridge end of the layout looking half decent attention has turned to the Dudley end of the new boards or the middle of the layout. Theres a few things that jarred about this scene now that it’s more open. Before you couldn’t really see them. The pavement doesn’t flow properly and there are big gaps at the end of the bridge girder. Also the lower part wasn’t finished. When I designed the bridge I did have the foresight to include a half etch to allow the rivets on this side to be punched through. However when I built it i didn’t bother! Ive already pulled up the road.

With the Stourbridge end of the layout looking half decent attention has turned to the Dudley end of the new boards or the middle of the layout. Theres a few things that jarred about this scene now that it’s more open. Before you couldn’t really see them. The pavement doesn’t flow properly and there are big gaps at the end of the bridge girder. Also the lower part wasn’t finished. When I designed the bridge I did have the foresight to include a half etch to allow the rivets on this side to be punched through. However when I built it i didn’t bother! Ive already pulled up the road.

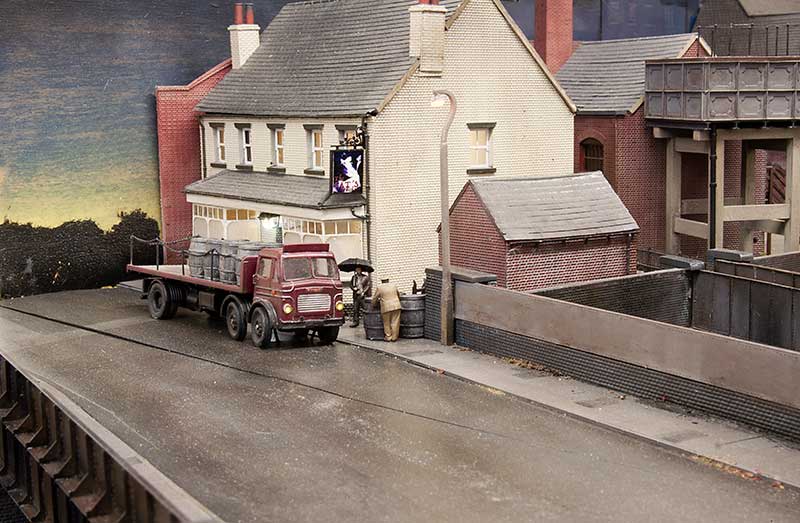

So the road and pavements have been redone. I made an overlay for the bridge from paper. The pub sign is from Model scenics and features our much missed cat Moo. The figures are from Modelu.

So the road and pavements have been redone. I made an overlay for the bridge from paper. The pub sign is from Model scenics and features our much missed cat Moo. The figures are from Modelu.

The bridge from track level. Ive added the retaining walls with some nifty top capping that Tim kindly cut for me.

The bridge from track level. Ive added the retaining walls with some nifty top capping that Tim kindly cut for me.

Turning around we see an overview of the somewhat neglected platforms.

Turning around we see an overview of the somewhat neglected platforms.

An overview of progress so far.

An overview of progress so far.

Ive added a scattering of people from Modelu and Airfix. I thought the lady with the umbrella was particularly suitable. I still need to do more work to bed this end of the building in. Considering this is the rush hour theres not many people about.

Ive added a scattering of people from Modelu and Airfix. I thought the lady with the umbrella was particularly suitable. I still need to do more work to bed this end of the building in. Considering this is the rush hour theres not many people about.

The station has 2 cats. The sensible one is Shadow while the mischievous one who wants to play is comet They are more interested in chasing each other than the local rat population!

The station has 2 cats. The sensible one is Shadow while the mischievous one who wants to play is comet They are more interested in chasing each other than the local rat population!

On the other platform a couple of elder ladies discuss the immanent closure of the station with the station master.

On the other platform a couple of elder ladies discuss the immanent closure of the station with the station master.

Agent  A gent waits for the bus. It’s late as usual!

A gent waits for the bus. It’s late as usual!

Now that the some of the lighting is in place a few dark shots.

Greenery and decoration.

I’ve reached the stage where all the significant greenery is pretty much done and I can move on to some titivating of parts of the layout.

I’ve made a basic wooden fence to block off the line that crossed the road originally. The rudimentary gate (which looks like it hasn’t been actually used for years) is simply a few bits of 1x1mm brass soldered together.

I’ve made a basic wooden fence to block off the line that crossed the road originally. The rudimentary gate (which looks like it hasn’t been actually used for years) is simply a few bits of 1x1mm brass soldered together.

Proverbially walking up the road a little we come to the station signs. These are based on a photo I found somewhere. The fading on the signs themselves was actually an accident. The result of me handling the printout a little too early.

Proverbially walking up the road a little we come to the station signs. These are based on a photo I found somewhere. The fading on the signs themselves was actually an accident. The result of me handling the printout a little too early.

Continuing our walk we come to this. What can be more of a model railway cliché than the good old bus on a bridge? Well since I am not going to be doing any buses for this layout I have gone for a midlands style bus stop instead. The main column was something I had in my spares box. The rain on the layout is always going to be going left to right as you look at it, so it makes sense that the autumn leaves and litter do the same. The top of the bridge is particularity known by the locals as being a bit blustery. (Theres actually a real location nearby known locally as ‘windy corner’)

Continuing our walk we come to this. What can be more of a model railway cliché than the good old bus on a bridge? Well since I am not going to be doing any buses for this layout I have gone for a midlands style bus stop instead. The main column was something I had in my spares box. The rain on the layout is always going to be going left to right as you look at it, so it makes sense that the autumn leaves and litter do the same. The top of the bridge is particularity known by the locals as being a bit blustery. (Theres actually a real location nearby known locally as ‘windy corner’)

Peering over the bridge we see the lower end of the station footpath. The Midland style fencing and wire fencing posts both come from Scale Model Scenery as does the little beware of trains sign.

Peering over the bridge we see the lower end of the station footpath. The Midland style fencing and wire fencing posts both come from Scale Model Scenery as does the little beware of trains sign.

Looking back at the bridge we just walked over. The girder is 2 of my previously designed etches combined together. I still need to add the top capping to the sloping walls yet.

Looking back at the bridge we just walked over. The girder is 2 of my previously designed etches combined together. I still need to add the top capping to the sloping walls yet.

Overview looking towards Stourbridge. The 2 buildings are still just loosely placed at this stage.

Overview looking towards Stourbridge. The 2 buildings are still just loosely placed at this stage.

… and towards Dudley. You’ll have to use your imagination for the moment for fill in the bridge and the wall on the left.

… and towards Dudley. You’ll have to use your imagination for the moment for fill in the bridge and the wall on the left.

Old warning sign from Ambis Engineering

Old warning sign from Ambis Engineering

A train! Remember those?

A train! Remember those?

The march of progress

Ive been a bit busy. All the track is not ballasted and the first stage of weathering in complete. I have also put the platforms in. The sides and tops were cut when I was over at Tims. The brick platform edges are something Tim developed and they do look really smart.

The sides and tops were cut when I was over at Tims. The brick platform edges are something Tim developed and they do look really smart.

Overview from the Stourbridge end.

Overview from the Stourbridge end.

And from the Dudley end

And from the Dudley end

Co-Bo lurks in the weeds.

Co-Bo lurks in the weeds.

Up until now i have resisted the urge to plonk the building in place but my resistance has now caved.

Up until now i have resisted the urge to plonk the building in place but my resistance has now caved.

View from under the bridge. This gives a good idea of the elevation changes in the yard. And before anyone says anything, doing the point rodding was probably a bit of a pointless exercise if I’m honest!

View from under the bridge. This gives a good idea of the elevation changes in the yard. And before anyone says anything, doing the point rodding was probably a bit of a pointless exercise if I’m honest!

Bitsa post

This post kind of jumps around a little but lets start with a simple wagon as we’ve not had one of those for a while.  LMS diagram 1973 mineral wagon. These were a little odd as they had no end doors just side ones. The model was created by splicing 2 sections of the Dapol (ex Airfix) mineral wagon body together and mating the result with a Parkside 12 ft wheelbase chassis. The W-irons are Bill Bedford, door springs Rumney models and buffers from Accurascale.

LMS diagram 1973 mineral wagon. These were a little odd as they had no end doors just side ones. The model was created by splicing 2 sections of the Dapol (ex Airfix) mineral wagon body together and mating the result with a Parkside 12 ft wheelbase chassis. The W-irons are Bill Bedford, door springs Rumney models and buffers from Accurascale.

Both the real Brettell Lane and Round Oak stations had central supports under the bridges. As this will be right at the end of the layout, under a bridge and in the dark I didn’t feel I had to go mad as a silhouette is pretty much all thats needed. The main pillars are actually nothing more than a couple of Hornby gradient supports spliced together.

Both the real Brettell Lane and Round Oak stations had central supports under the bridges. As this will be right at the end of the layout, under a bridge and in the dark I didn’t feel I had to go mad as a silhouette is pretty much all thats needed. The main pillars are actually nothing more than a couple of Hornby gradient supports spliced together.

I mentioned in a recent post that i needed to reverse my signal box so the steps are at the opposite end. Thats ticked off now and the results can be seen above. To see the original build click here.

I mentioned in a recent post that i needed to reverse my signal box so the steps are at the opposite end. Thats ticked off now and the results can be seen above. To see the original build click here.

Moving back to the layout itself the much modified Airfix crane has now been planted and the yard track has been ballasted and suitably ‘neglected’.

Moving back to the layout itself the much modified Airfix crane has now been planted and the yard track has been ballasted and suitably ‘neglected’.

Overall view of the yard so far.

Overall view of the yard so far.

Landscaping and a couple of firsts.

Don’t worry, I’ve not ditched model trains and took up gardening. As far as I am concerned a garden is just somewhere where a model railway shed should live!

With the track and wiring done on Brettell Road part 2 thoughts have turned to the landscaping of the yard.  Before I could start on the yard I needed to get the road in as this will need to be blended into the yard. The parts for this were cut out at Tim’s but I did add a layer of 1mm balsa to the road and sanded a camber into it. The thing with laser cutters is they are so neat. By using 2mm mdf for the pavements i could carve away some of the slabs to make it all look a bit more scruffy. I also cut a few of the slabs out completely on the laser so that I could add plasticard instead and do a couple of raised slabs. Brettell Road is set well before the ‘where theres blame theres a claim’ culture. I guess people back then just looked where they were going or called themselves an idiot if they ended up on their backsides!

Before I could start on the yard I needed to get the road in as this will need to be blended into the yard. The parts for this were cut out at Tim’s but I did add a layer of 1mm balsa to the road and sanded a camber into it. The thing with laser cutters is they are so neat. By using 2mm mdf for the pavements i could carve away some of the slabs to make it all look a bit more scruffy. I also cut a few of the slabs out completely on the laser so that I could add plasticard instead and do a couple of raised slabs. Brettell Road is set well before the ‘where theres blame theres a claim’ culture. I guess people back then just looked where they were going or called themselves an idiot if they ended up on their backsides!

This is my nod to Brierley Hill’s level street. Which if you’ve ever been there, is anything but level! At the bottom is a now abandoned level crossing (the real Level street had 2 that were part of the Round Oak system). The line it was on now forms the back siding. The road will need more work yet and weathering but this was far enough to let me move to the yard.

I’ve never done inlaid track before and, added to the bright idea to have different levels, I figured the easiest way would be to infill the gaps with layers of balsa The top layer is 1mm thick and is glued to various different shapes underneath as I didn’t want it to be all that flat. The infill in the track is 1.5mm balsa as I figured a half mill difference between the surface and the rail would aid track cleaning and wouldn’t be noticeable. I used track pins to hold it all together as well as PVA. Incidentally, I think this was the first time I’ve ever brought track pins!

I’ve never done inlaid track before and, added to the bright idea to have different levels, I figured the easiest way would be to infill the gaps with layers of balsa The top layer is 1mm thick and is glued to various different shapes underneath as I didn’t want it to be all that flat. The infill in the track is 1.5mm balsa as I figured a half mill difference between the surface and the rail would aid track cleaning and wouldn’t be noticeable. I used track pins to hold it all together as well as PVA. Incidentally, I think this was the first time I’ve ever brought track pins!

Despite my half mil’ gap idea i was still a little concerned that track cleaning would result in patches of nice fresh wood showing through. So rather than paint I decided to stain the wood black.

Despite my half mil’ gap idea i was still a little concerned that track cleaning would result in patches of nice fresh wood showing through. So rather than paint I decided to stain the wood black.

Time for another new (to me) product. I’ve used 2 colours of ‘mud’ from WWS Scenics. Peat and dark brown. These are like a very smooth liquidly filer. I used the peat first with the dark brown over the top. Applied with a plastic spatular and then stippled with a large brush. Ive also added some tire marks and a light sprinkle of chinchilla dust while it was still wet. More to do to it yet but I’m pleased with how it’s coming along so far. Lets just say the yard at Brettell Road was somewhat agricultural! For WWS muds click here.

Tracks and tweaks.

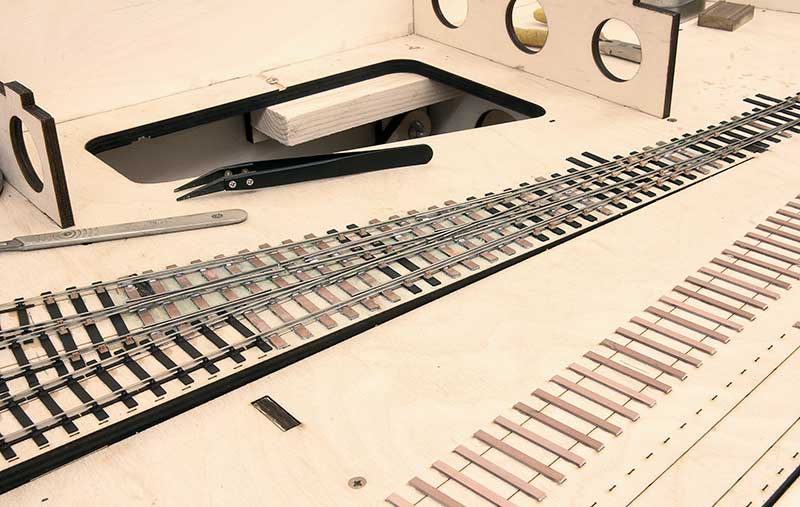

Been busy doing the fiddly bits of track for Brettell Road part 2.

Ok, this is just a B9 on a slight curve, not exactly fiddly.

Ok, this is just a B9 on a slight curve, not exactly fiddly.

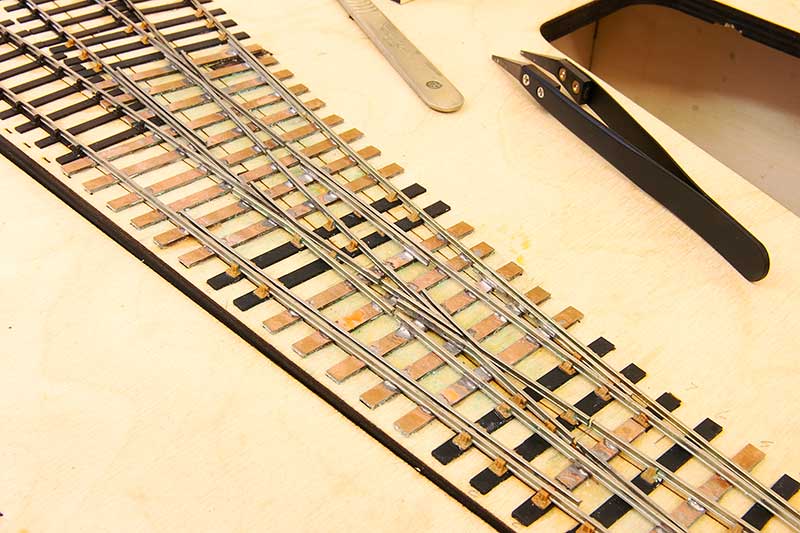

This is a bit more entertaining though. Ive tried a slightly different approach from my usual norm by using more copper clad and building more in situ than I usually do. I normally build the crossing assembly away from the layout but decided this time to only assemble the vees themselves remotely. I think its a bit quicker and allows a little more wiggle room doing it this way.

This is a bit more entertaining though. Ive tried a slightly different approach from my usual norm by using more copper clad and building more in situ than I usually do. I normally build the crossing assembly away from the layout but decided this time to only assemble the vees themselves remotely. I think its a bit quicker and allows a little more wiggle room doing it this way.

The view from the bridge.

The view from the bridge.

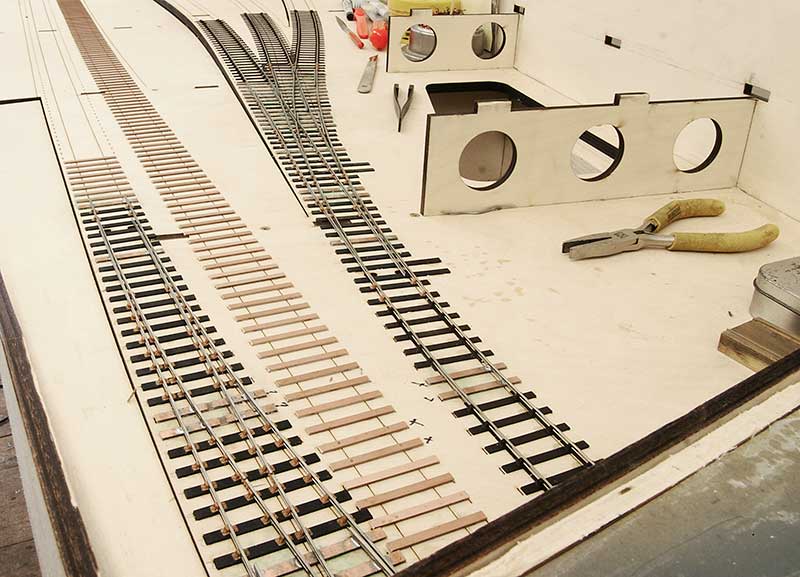

No matter how designed you think something is theres always some tweaks needed when you see the thing in the flesh. I never noticed how the 2 vees had ended up virtually on top of each other.

No matter how designed you think something is theres always some tweaks needed when you see the thing in the flesh. I never noticed how the 2 vees had ended up virtually on top of each other.

You can see here how the middle road has been realigned. The original alignment showing through under the sleepers.

You can see here how the middle road has been realigned. The original alignment showing through under the sleepers.

Another tweak is the position of the signal box. I don’t think I fully took into account the curve and the sighting lines are worse than I thought they would be where I put it originally.

Another tweak is the position of the signal box. I don’t think I fully took into account the curve and the sighting lines are worse than I thought they would be where I put it originally.

By moving it to to the other platform and along to the left a bit the sighting lines are much better.

So the signal box will go here instead. I will need to move the steps to the near end and I plan to fit deeper windows so that it more like a type 3 box.

Brettell Road part 2

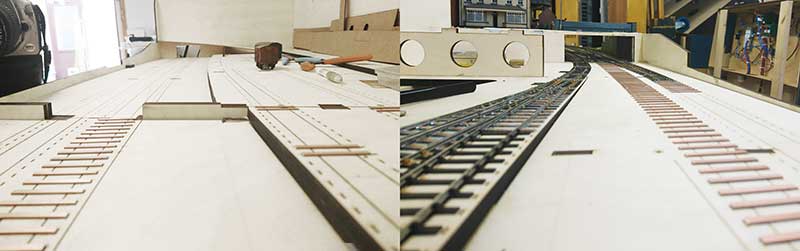

I guess I was supposed to be here about a year ago but Covid happened. I actually had a trip over to Tims planned between the first and second lock down but that got delayed to the start of this week. Tim Kindly agreed to me using his laser cutters for 3 days but in the event it only took 2 to do the new boards for Brettell Road. I must say there was only a few of the most minor amendments needed which I was very pleased about and unlike some of our previous efforts next to no scrap bits this time!

Here we see the new board meeting the old. Perhaps one of the biggest advantages of drawing baseboards up digitally and cutting them on a machine is that everything should be consistent. In the event the track bed was about a mill and half too high which considering I had rebuilt the main lines wasn’t to bad at all. Nothing a few minutes with a saw and a chisel didn’t fix anyway! The end back scene from the original layout has been cut away.

Here we see the new board meeting the old. Perhaps one of the biggest advantages of drawing baseboards up digitally and cutting them on a machine is that everything should be consistent. In the event the track bed was about a mill and half too high which considering I had rebuilt the main lines wasn’t to bad at all. Nothing a few minutes with a saw and a chisel didn’t fix anyway! The end back scene from the original layout has been cut away.

Overview of the 2 new boards. Unlike the previous boards the mainline is flat on these boards with the yard rising behind them. Kings Heath station was the inspiration for this arrangement. Time will tell if I need to get creative about how the wagons in the yard stay put.

Overview of the 2 new boards. Unlike the previous boards the mainline is flat on these boards with the yard rising behind them. Kings Heath station was the inspiration for this arrangement. Time will tell if I need to get creative about how the wagons in the yard stay put.

Looking towards Stourbridge. The platforms will fill all of the view here along the mainlines I have a thing for stations with much longer platforms than the trains that serve them. I wonder if its because much of the northern half of the North Warwickshire Line had stations like this (as a kid our garden backed onto it)?

Looking towards Stourbridge. The platforms will fill all of the view here along the mainlines I have a thing for stations with much longer platforms than the trains that serve them. I wonder if its because much of the northern half of the North Warwickshire Line had stations like this (as a kid our garden backed onto it)?

With hindsight it was probably a good thing I was a tad obsessive about the buildings and detailed up the side of the pub that, at the time of building it, I never thought anyone would see!

With hindsight it was probably a good thing I was a tad obsessive about the buildings and detailed up the side of the pub that, at the time of building it, I never thought anyone would see!

Nothing new here

With the point rodding redone and signal wires back in place theres not really anything left to do on Brettell Road part 1. I was hoping to embrace the latest technology with the rodding and decided to go with 3d printed BR stools from Modelu. However those didn’t work out for me at all and proved to be far too fragile. Ive sent them all back and Alan is going to investigate as he believes there was a problem with the resin. I’ll do a follow up post when he comes back with his findings. So as the old adage goes, sometimes its best to stick with what you know I went back to the trusty Brassmasters etched ones instead.

With the point rodding redone and signal wires back in place theres not really anything left to do on Brettell Road part 1. I was hoping to embrace the latest technology with the rodding and decided to go with 3d printed BR stools from Modelu. However those didn’t work out for me at all and proved to be far too fragile. Ive sent them all back and Alan is going to investigate as he believes there was a problem with the resin. I’ll do a follow up post when he comes back with his findings. So as the old adage goes, sometimes its best to stick with what you know I went back to the trusty Brassmasters etched ones instead.

The cranks are also Brassmasters although I’ve used the MSE bases as I thought they were better. The rodding itself and signal posts are also from MSE with the signal wires from ezline. Unlike the previous version where I made some of the point rodding work, just to see if i could, I didn’t feel any need to to it again.

The cranks are also Brassmasters although I’ve used the MSE bases as I thought they were better. The rodding itself and signal posts are also from MSE with the signal wires from ezline. Unlike the previous version where I made some of the point rodding work, just to see if i could, I didn’t feel any need to to it again.

A few more detectors for the ground signals were knocked up from bits of brass and my rain technique of coats of Tamiya smoke and AK wet effects fluid reapplied. I guess you could say I’m back to where I was a few months ago!

A few more detectors for the ground signals were knocked up from bits of brass and my rain technique of coats of Tamiya smoke and AK wet effects fluid reapplied. I guess you could say I’m back to where I was a few months ago!

Theres something oh so familiar about glimpses of grubby track between bridges and retaining walls.

Theres something oh so familiar about glimpses of grubby track between bridges and retaining walls.

At the other end of the layout the extra bits of the bridges have been added.

At the other end of the layout the extra bits of the bridges have been added.

One thing I forgot to mention before is this stuff. Its great for fixing ballast and while its no where near as cheap as the traditional PVA/ water/ washing up liquid concoction it can be used straight from the bottle with no messing around wetting everything first.

One thing I forgot to mention before is this stuff. Its great for fixing ballast and while its no where near as cheap as the traditional PVA/ water/ washing up liquid concoction it can be used straight from the bottle with no messing around wetting everything first.

Wires and signals

Part of the process in upgrading Brettell Road and preparing it for part 2 was to redo the wiring. Those that have been following from the start will recall that it was initially only a plaything and not an exhibition layout and the wiring reflected that being just 4 wired between boards. 2 for the DCC and 2 for the AC supply. A concession was made after the first show to provide short protection for each board but its not really how things should be done so its been mostly stripped out and done again.

So now the DCC is split into 3 sections. One for the yard, one for the mainlines and one for the accessories. Theres little point having short protection if said short cuts off the ability to throw the points and resolve it. The AC is also split into 2 sections as well, the second being a DC supply for LEDs. You can use AC for LEDs anyway but the flicker can be noticeable sometimes. So now theres 10 wires between boards instead.

Signals

The new arrangement for entering the yard has required a few new signals as well.  Mainly a couple of ground signals from the MSE kits. I need a couple more for part 2 (one of which is a double) so I built them all together. these are powered by servos controlled by a Tam Valley control board.

Mainly a couple of ground signals from the MSE kits. I need a couple more for part 2 (one of which is a double) so I built them all together. these are powered by servos controlled by a Tam Valley control board.  I guess this also comes under signals? A simple limit of shunt sign from a MSE lamp a bit of brass tube and some microstrip.

I guess this also comes under signals? A simple limit of shunt sign from a MSE lamp a bit of brass tube and some microstrip.

Below a couple of mood shots .

No going back now! part 2

Well the engineering works, true to form, over ran and took a bit longer than I expected. However the mini people of Brierley Hill will be pleased to hear that services can resume. I used to be a fan of the JLTRT track colour spray paint but as that range is long gone now and my last can was pretty much done for an alternative was required. Halfords do a ‘camouflage’ range of very matt colours in their rattle cans and the brown is ideal as a basic track colour.

I used to be a fan of the JLTRT track colour spray paint but as that range is long gone now and my last can was pretty much done for an alternative was required. Halfords do a ‘camouflage’ range of very matt colours in their rattle cans and the brown is ideal as a basic track colour.  The completed track ballasted and weathered from under the bridge. The blocks on the right are for the point rodding and I haven’t fitted the point motors yet.

The completed track ballasted and weathered from under the bridge. The blocks on the right are for the point rodding and I haven’t fitted the point motors yet.

The left hand end from the other side of the bridge. I have a couple of ground signals to add yet.

The left hand end from the other side of the bridge. I have a couple of ground signals to add yet.

And the right hand end. This is the end that required the most adjustment of whats already there.

And the right hand end. This is the end that required the most adjustment of whats already there.  The bridges over the canal have been adapted to fit in their new locations. I still have a bit of work to bed them in properly and I intend to fit a couple of central girders between the tracks on both levels.

The bridges over the canal have been adapted to fit in their new locations. I still have a bit of work to bed them in properly and I intend to fit a couple of central girders between the tracks on both levels.  The nearer buffer stop has been repositioned slightly and a new bridge built. I decided to angle it a little and do a bit of scruffy road to go behind it.

The nearer buffer stop has been repositioned slightly and a new bridge built. I decided to angle it a little and do a bit of scruffy road to go behind it.  Old meets new!

Old meets new!

No going back now! Part 1

It seems that the good folk of Brierley Hill need to rely on buses for a while… …Brettell Road is currently somewhat disrupted! Work progressing on the plan to double track the layout. One of the advantages of designing a layout on a computer and having a friendly laser cutting chap is you can design bits to replace things you really should have thought more about the first time!

…Brettell Road is currently somewhat disrupted! Work progressing on the plan to double track the layout. One of the advantages of designing a layout on a computer and having a friendly laser cutting chap is you can design bits to replace things you really should have thought more about the first time!

Ive talked before about the regret at not making the layout a double track and I’ve also touched on using MDF as a trackbed which turned out to be a tad too unstable. The main lines have been replaced with 6mm ply and a hole cut for it to sit in. Pictures of Brettell Lane in the period show some encroachment of flat bottom trackwork but in the form of pointwork. Further down the line, north of Dudley the Midland lines were also flat bottom in the period I am modelling and since Brettell road has always been more Midland anyway I decided to go with flat bottom trackwork for the plain lines. Specifically mills clips courtesy of Colin Craig. (the actual clips will be added after testing.

Chains of slips under bridges all seem oddly familiar for some reason! Like my other model nothing in this one is straight either!

Thanks to Colin and Tim for their assistance in supplying bits.

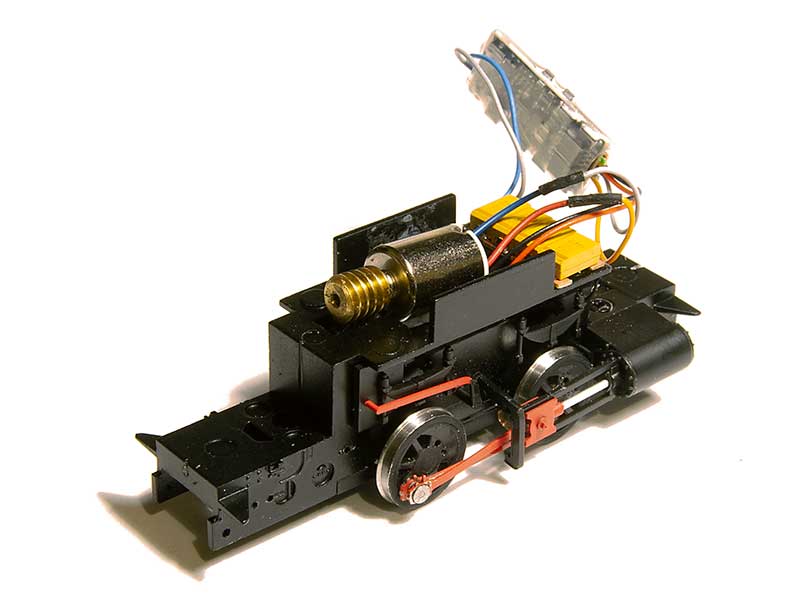

I never really intended to go for the little Hatton’s Barclay tank despite the Earl of Dudley’s railway having quite a few of them. But one popped up for a reasonable sum on ebay with a best offer option. As it would be a nice to have I put in a cheeky offer and the seller accepted it!

I never really intended to go for the little Hatton’s Barclay tank despite the Earl of Dudley’s railway having quite a few of them. But one popped up for a reasonable sum on ebay with a best offer option. As it would be a nice to have I put in a cheeky offer and the seller accepted it!

As can be seen in the previous picture there’s quite a noticeable gap between the chassis and the wheels. Of the limited detail on the chassis a lot of it pugs in as separate bits so its a relatively easy job to make some new overlays from 60thou plasticard and plug the bits back in.

As can be seen in the previous picture there’s quite a noticeable gap between the chassis and the wheels. Of the limited detail on the chassis a lot of it pugs in as separate bits so its a relatively easy job to make some new overlays from 60thou plasticard and plug the bits back in.  One thing I would advise though is to cut away the original chassis at the points shown (where the NEM coupling pocket is) as you will end up with very chunky and visible frames at the ends of the loco. Might be better to do 20 thou overlays and space them out so they are nice and thin. The arrangement of the brake shoes on the EoD locos seems the opposite way round to the way Hattons had modelled them with the shoes in front of the wheels not behind them and the linkages not visible at all. so these were rearranged. You can see the front crank pin screw in this picture. I also changed the front step to match prototype photos.

One thing I would advise though is to cut away the original chassis at the points shown (where the NEM coupling pocket is) as you will end up with very chunky and visible frames at the ends of the loco. Might be better to do 20 thou overlays and space them out so they are nice and thin. The arrangement of the brake shoes on the EoD locos seems the opposite way round to the way Hattons had modelled them with the shoes in front of the wheels not behind them and the linkages not visible at all. so these were rearranged. You can see the front crank pin screw in this picture. I also changed the front step to match prototype photos.

The rear of the cab. EoD locos had 2 types of cab, an enclosed one with 3 windows and this open version. The enclosed one is available from Planet industrials as a detailing kit. Given the layout is set in the rain my mini driver and fireman must be cussing me for not going for that one! My first thought was to scratchbuild a new rear cab from brass for strength but I decided to cut away the RTR one first to see if that would work instead, as can be seen it did. The handbrake is the supplied RTR one

The rear of the cab. EoD locos had 2 types of cab, an enclosed one with 3 windows and this open version. The enclosed one is available from Planet industrials as a detailing kit. Given the layout is set in the rain my mini driver and fireman must be cussing me for not going for that one! My first thought was to scratchbuild a new rear cab from brass for strength but I decided to cut away the RTR one first to see if that would work instead, as can be seen it did. The handbrake is the supplied RTR one