Forever Autumn

Wandering around at the back end of October last year I became aware that Brettell Road might not have enough fallen leaves to accurately represent the time of the year I was trying to depict. Theres 2 types of autumn. The really pretty one thats kind of fleeting and gets used in image libraries and on jigsaws. Then theres the drudgy one that doesn’t but hangs around a lot longer. You can probably guess which one of those two I decided I wanted.

On the backscene on the end of the layout theres a line of trees that hints at the line continuing to curve to the right as you head towards Stourbridge. So these are the source for a spot of leaf litter. Ive always assumed that the wind is blowing from the left as you look at the layout and the weathering of the wet bits has always reflected this. To get the mulch I wanted I used a combination of kids power paint scatter and a couple of different types of autumnal leaves from AK Interactive mixed in place on the layout in a somewhat haphazard way and sealed with AK sand and gravel fixer. Once dry it was given another coat of wet effects fluid to blend it all together. I included a little more overflow down onto the platform and the tracks and I might revisit this and add more along the platform edge. Although the line speed on the layout is only 35mph and most trains entering the platform are going slower than that it’s still reasonable to assume trains will blow leaves from the other side of the bridge along with them.

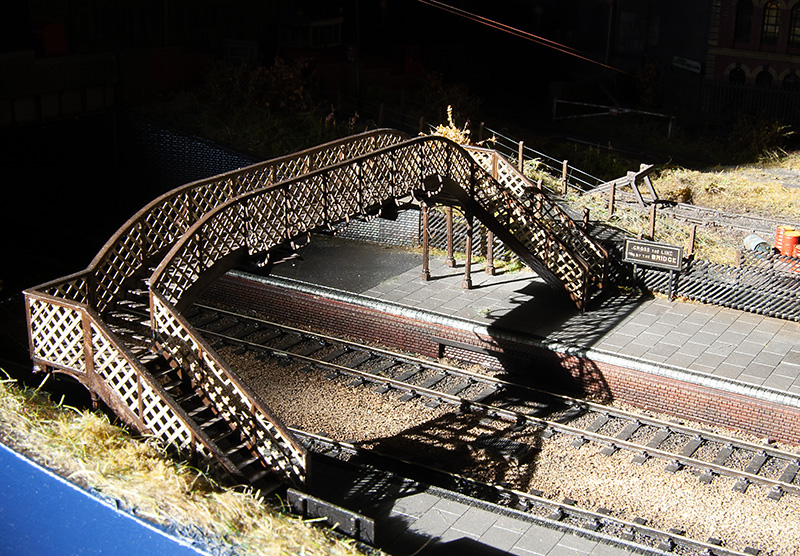

This is the central bridge and Ice assumed that there are more tress behind me. Again with a bias toward the leaves being blown from the left. Im not sure if they look a little bright here (no idea why as its the same technique using the same stuff) but next time I am weathering some underframes I might give a very light coat of dark mud to tone them down a little.

This is the central bridge and Ice assumed that there are more tress behind me. Again with a bias toward the leaves being blown from the left. Im not sure if they look a little bright here (no idea why as its the same technique using the same stuff) but next time I am weathering some underframes I might give a very light coat of dark mud to tone them down a little.

The same scene as above in a more intentional lighting.

The same scene as above in a more intentional lighting.

While I had the wet effects fluid out I gave the platforms another coat. Here we see the station in a quiet moment.

While I had the wet effects fluid out I gave the platforms another coat. Here we see the station in a quiet moment.

Variations on a theme – More vans

My somewhat hopeless addiction to building kits continues, I passed the point of having enough a long long time ago but there you go. This time all variations on types I’ve built before. Starting with the classic Airfix meat van. Or in this case just the ends of one and even then only part of the ends! Some meat vans lost their side vents and all but the top end vent. The Airfix ends are kinda chunky and can easily take having sections of them cut out and replaced with bits of plasticard. The rest of the van is all Parkside. Behind it is a standard Parkside plywood sided kit built as a fruit version.

My somewhat hopeless addiction to building kits continues, I passed the point of having enough a long long time ago but there you go. This time all variations on types I’ve built before. Starting with the classic Airfix meat van. Or in this case just the ends of one and even then only part of the ends! Some meat vans lost their side vents and all but the top end vent. The Airfix ends are kinda chunky and can easily take having sections of them cut out and replaced with bits of plasticard. The rest of the van is all Parkside. Behind it is a standard Parkside plywood sided kit built as a fruit version.

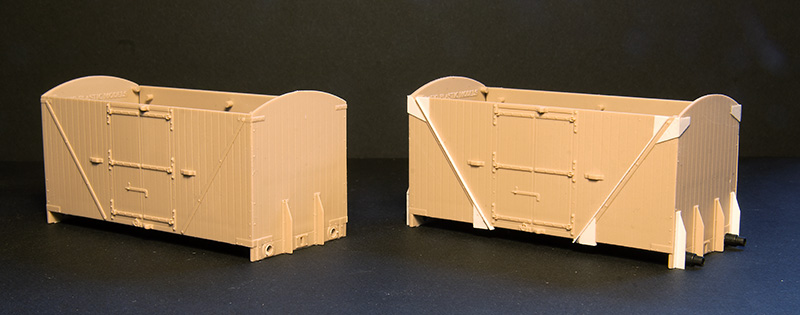

The Ratio Banana van kit. These are the second and third times I’ve built one of these and I’ve still yet to build one as the kit intended. On the left is the standard body and on the right modifications to convert it into the diagram 1/224 version.

The first body was mated with a 9ft wheelbase chassis (stretched at the ends to fit) to produce a ex-LMS D1672 insulated meat van. By the time these were in BR service they lost the modifications that made them interresting. Those being roof mounted ice boxes and end ladders. Note the different wheels as per the prototype image in LMS wagons volume 1.

The first body was mated with a 9ft wheelbase chassis (stretched at the ends to fit) to produce a ex-LMS D1672 insulated meat van. By the time these were in BR service they lost the modifications that made them interresting. Those being roof mounted ice boxes and end ladders. Note the different wheels as per the prototype image in LMS wagons volume 1.

And the Diagram 1/224 version. Mounted on a detailed Red Panda chassis. Im just waiting for my friend to supply me some flexible steam heat hoses.

And the Diagram 1/224 version. Mounted on a detailed Red Panda chassis. Im just waiting for my friend to supply me some flexible steam heat hoses.

Some meat van variations – Left to right – the modified one shown at the start of the post. A similar one by the same method but with unmodified ends. A bog standard Parkside insulated one. The good old air-fix original (with Parkside doors and underframe) and the D1672 version.

And similar for Banana vans – Left to right D2111 LMS van from the Ratio kit on a shortened Parkside chassis. The Diagram 1/224 van. The ex GWR Y7 i featured last time and 2 Diagram 1/246 from the old Hornby Dublo bodies mounted on detailed Red Panda Chassis.

A few old kit builds

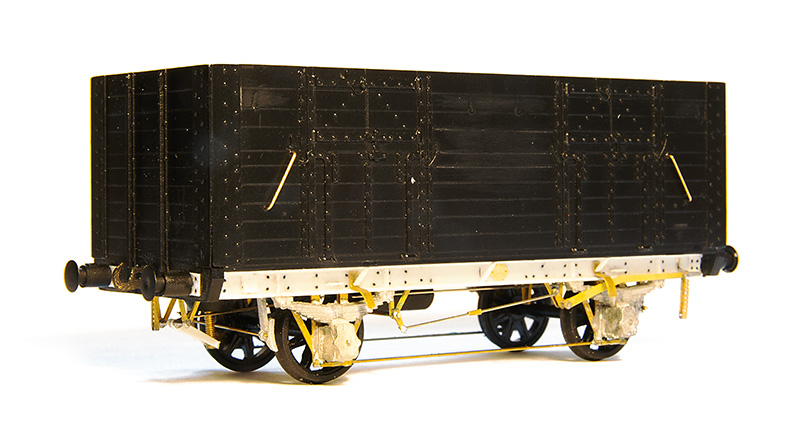

Been filling the odd moment here and there with some kit builds of fairly old vintage. The above is an LMS 22t tube from the old Ian Kirk kit. I replaced the bearings with MJT roller bearings based on a photo of a very similar wagon in Don Rowlands Twilight Of The Goods book. The hand brakes (which are too long in the kit as provided and are only one type) are spares from the Parkside 12ft chassis kit.

Digram 1/120 LNER open from the Parkside kit. Whilst this kit is still readily available it is one of their older toolings. I enjoyed doing the weathering on my china clay rake and have seen photos with similarly weathered opens in normal freight trains so I returned to that for this one. The cattle van is a diagram w5 from the Coopercraft kit. Both have had extra detail with the GWR brakes coming from Mainly Trains and Morgan Designs etched parts

Next up another Ian Kirk kit, this time for the GWR mink C. I used the ends from the Ratio GWR 12t van kit, the ones in the kit had end vents and looked too narrow to me. I’ve added extra details to the body and underframe. Being on a 12ft wb underframe it’s something a little different.

Next up another Ian Kirk kit, this time for the GWR mink C. I used the ends from the Ratio GWR 12t van kit, the ones in the kit had end vents and looked too narrow to me. I’ve added extra details to the body and underframe. Being on a 12ft wb underframe it’s something a little different.

Finally the left over sides from the above model were mated with Airfix cattle van ends to produce a Fruit B Diagram y7 banana van (I’m not sure that this designation is correct but it what the Didcot Railway Centre website refers to them as). The end vents were scratch-built and the underframe is a Parkside 9ft one with the ends stretched a bit.

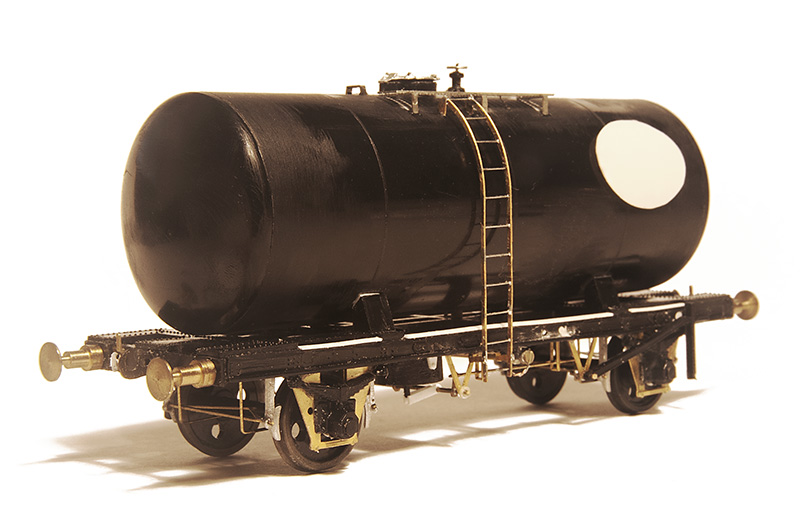

Not me

Appearing at Scaleforum was this Hurst Nelson 14T chlorine tank, incredibly generously donated by Colin Craig. He was building a batch for Mostyn and added an earlier version for me. These would not have ventured to the Black Country but years ago I helped Dave Clarke, Along with Simon Stephens, take out his layout Amlwch to various shows around the country. Amlwch (pronounced Amlook) was the location of the Associated Octel plant and while the exchange sidings for it never featured on the layout and we never had the chemical tank trains its a nice little nod to a bit of my personal modelling history.

Appearing at Scaleforum was this Hurst Nelson 14T chlorine tank, incredibly generously donated by Colin Craig. He was building a batch for Mostyn and added an earlier version for me. These would not have ventured to the Black Country but years ago I helped Dave Clarke, Along with Simon Stephens, take out his layout Amlwch to various shows around the country. Amlwch (pronounced Amlook) was the location of the Associated Octel plant and while the exchange sidings for it never featured on the layout and we never had the chemical tank trains its a nice little nod to a bit of my personal modelling history.

None of this wagon is any of my work. I did tweak the weathering a little from how Colin supplied it as the top of a white tank in the steam era wouldn’t be a clean as in Mostyn’s diesel era. I added the required wet look for Brettell road.

For more on Associated Octel click here.

Next up another tank that I’ve not had a lot to do with really. The recently introduced demountable tank wagon RTR from Clarke Railworks. I rarely buy anything new RTR and this is the first brand new rail vehicle I’ve brought from any of the new generation manufacturers. In fact it’s the first new RTR thing I’ve brought since 2017 and the time before that was 2012 I think. I seriously doubt I’m paying any bonuses in RTR land at the moment.

Next up another tank that I’ve not had a lot to do with really. The recently introduced demountable tank wagon RTR from Clarke Railworks. I rarely buy anything new RTR and this is the first brand new rail vehicle I’ve brought from any of the new generation manufacturers. In fact it’s the first new RTR thing I’ve brought since 2017 and the time before that was 2012 I think. I seriously doubt I’m paying any bonuses in RTR land at the moment.

So the wagon then, nice box and instruction booklet (looking at youtube reviewers these things seem important). The box will still look nice in my bin too! To be fair the instruction booklet is nicely laid out with clear illustrations of how to swap the wheels for em/P4. Which is dead easy, P4 wheels just drop in once the brake rigging has been unclipped and brass bearings are already installed. The brake shoes are kind of wide for 00 and a bit narrow for p4 but not enough to make you want to faff about moving them. The wagon weighs 30 grams out of the box which is lighter than my aimed for standard of 50g but some test shuffling around on Brettell Road didn’t show up any problems with this.

The couplings were replaced for Smiths and the (strangely) missing brake gear safety loops added. There a bit of a trench down the side of the tank and this was filled with Mr Surfacer 1000 liquid filler and gently sanded back. The colour was matched from a mix of blue and black. You don’t want to completely eradicate the line as it is visible on the real wagon. I think the branding should be parallel to the wagon and not the tank (which itself slopes at one end) but I might be wrong. Either way I left it as it was. The lamp irons were painted black (white lamp irons weren’t a thing yet) and that was about it, with the obligatory weathering of course.

Scaleforum 2025 ticked off

Well Scaleforum 2025 is ticked off as is my exhibition diary for this year. I’m happy to report that everything went very well and all that effort put into amending the cassettes post York was well and truly worth it. Theres a small list of things to fiddle with, there always is, and less than an handful of errant wagons are waiting to be spoken to. We all enjoyed ourselves and I’d like to extend my thanks to the Scalefour society and everyone who took the time to stop by. Many kind words were humbly received.

It’s changed a bit since the first Scaleforum we did back in 2017. Next up is Macclesfield in April 2026.

It’s changed a bit since the first Scaleforum we did back in 2017. Next up is Macclesfield in April 2026.

A bit of Deja-vu

Ive been wagon building again but but its all stuff I’ve done before (well sort of)

Starting with this little selection of fairly mundane vans (with a cheeky Airfix mineral tacked on the end). The nearest van is a Southern diagram 1452 plywood van from the Ratio kit. I used a parkside underframe and reprofiled the roof as the moulding flared out too much at the bottom. The repair patches are a neat little etch from RT models. The next one along is a bog standard Br 12 tonner from the Parkside kit and the cattle van is Airfix. You can see what i did to an earlier one by clicking here.

Next up an ex GWR Y8 fruit van. This uses Bachmann RTR sides and Parkside ends as the RTR body is too wide. Steve Carter has already written about this conversion on Kier Hardy’s site so there’s no real point in repeating whats already put there. Heres a link scroll to about halfway down. Just a quick note of thanks to Richard Oldfield for assisting with locating some buffers. On the 3 10ft wheelbase vans I’ve deviated from my normal approach of building them rigid by using the Dave Bradwell spring plates. Just as a bit of an experiment. See here – about halfway down

Ive been here before too – LMS D1994 milk tank from mostly Rumney models etches with a Lima Tank. My original one is the one on the right. As a slight variation the one I’ve just done uses the earlier style of underframe. (see here for the original build)

And D2173. These had sloping tanks and discharge at only one end. Justin kindly supplied me a test etch for the platform.

And D2173. These had sloping tanks and discharge at only one end. Justin kindly supplied me a test etch for the platform.

My little milk train in its entirety.

My little milk train in its entirety.

Project 2f part 2

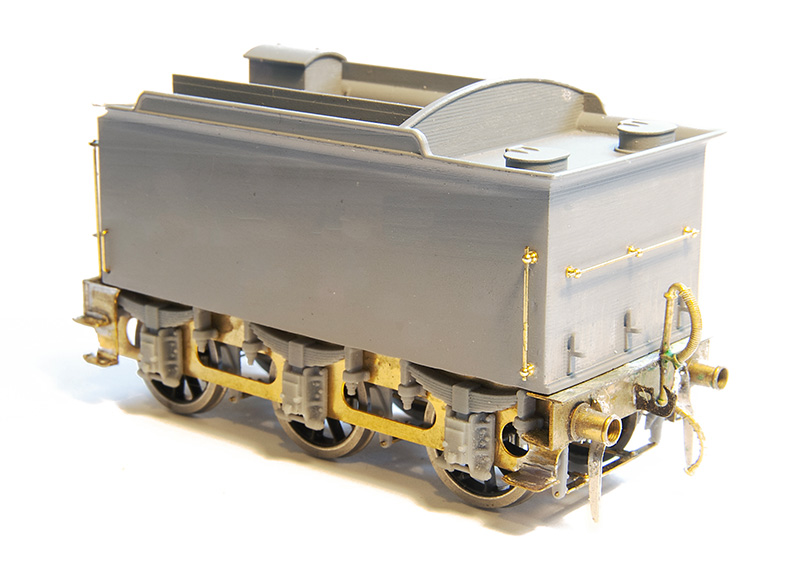

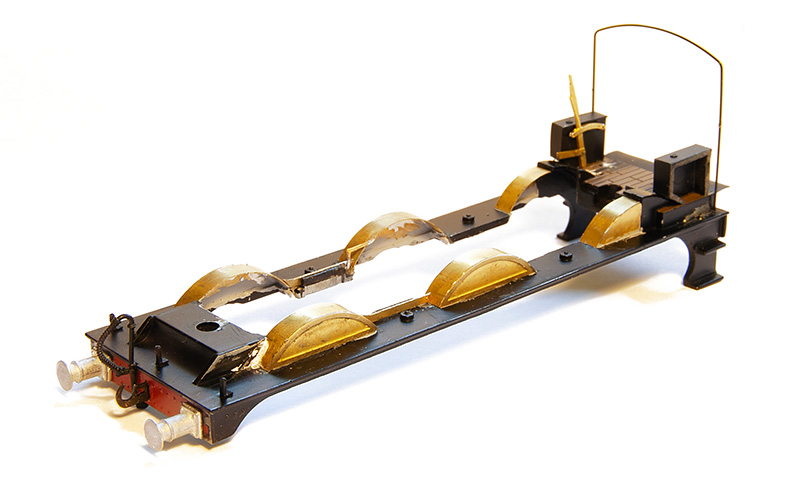

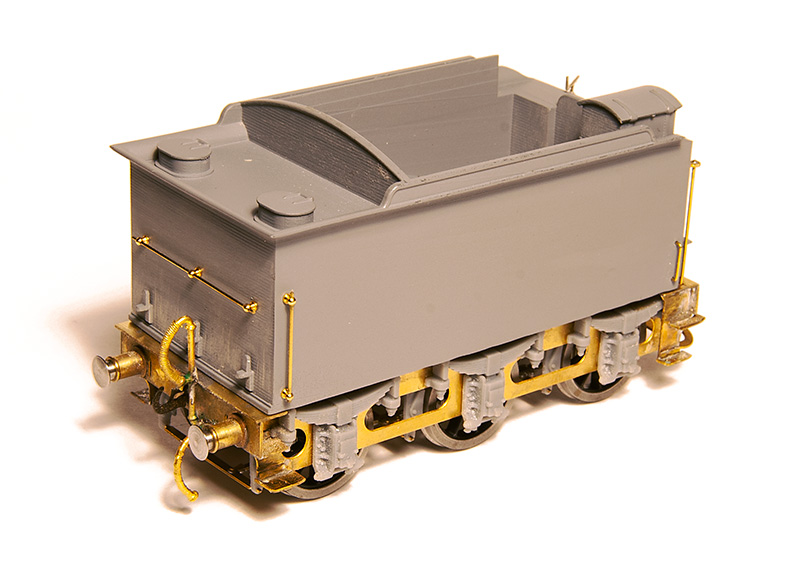

Concluding my 2F project by starting with the tender The coal rails were from the kit as was the tool box.

Concluding my 2F project by starting with the tender The coal rails were from the kit as was the tool box.

Lamp irons from Stenson Models – Vac pipe from Lanarkshire Models.

On the inside I made a representation of the coal space from thin plasticard – I wasn’t too fussed about blending this into the existing space as it will be covered in coal.

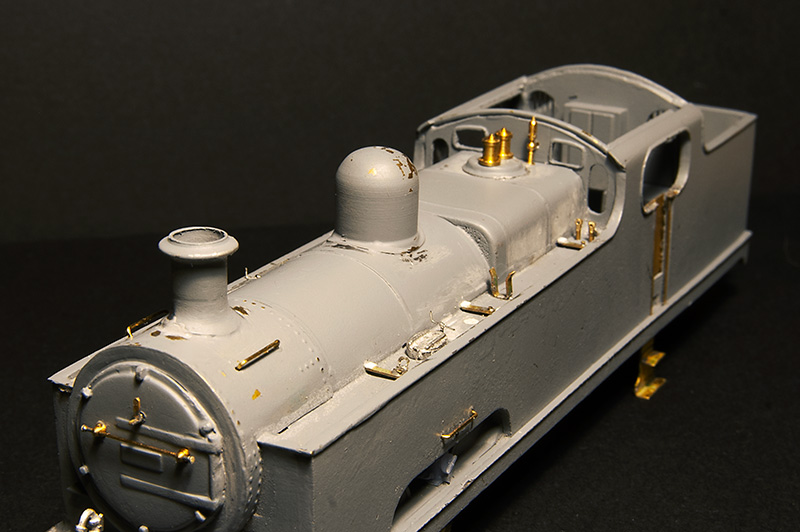

On to the loco then, with details fitted.

The washout plugs are kind of loco specific so as always – check your prototype. Also check the date. I found another picture of 58185 at Harbourne, so the same loco, at the same place, even under the same bridge, but as it was a little later the smokebox door was different. Alan Gibson do some nice lost wax washout plugs (I used them on my flatiron) but he hadn’t got any so i knocked some up from bits of brass.

The kit includes a casting for the injectors but its the later combined type. I previously made the version I needed for my 2441 tank from bits of wire and tube so I just copied what i did last time.

The kit includes a casting for the injectors but its the later combined type. I previously made the version I needed for my 2441 tank from bits of wire and tube so I just copied what i did last time.

Some rudimentary cab details – I tend not to go too mad on this stuff as there will be a crew in the way. The floor is a bit of lead as any weight helps. The inside of the firebox is also lined with lead.

Some rudimentary cab details – I tend not to go too mad on this stuff as there will be a crew in the way. The floor is a bit of lead as any weight helps. The inside of the firebox is also lined with lead.

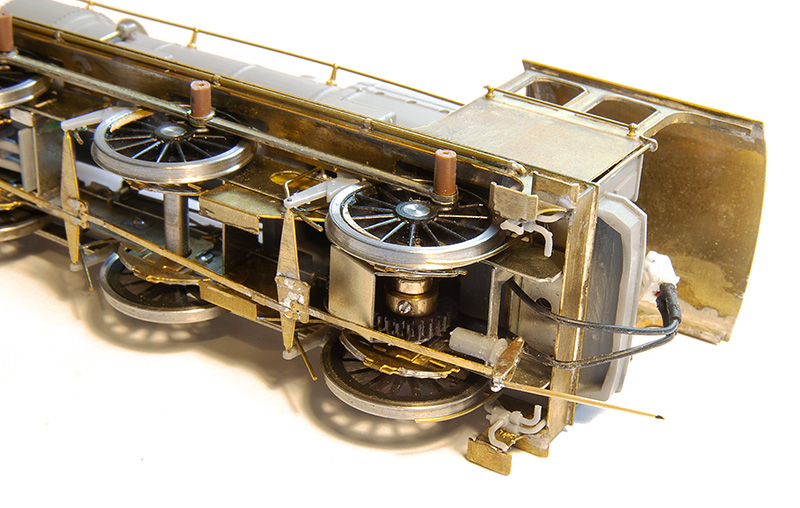

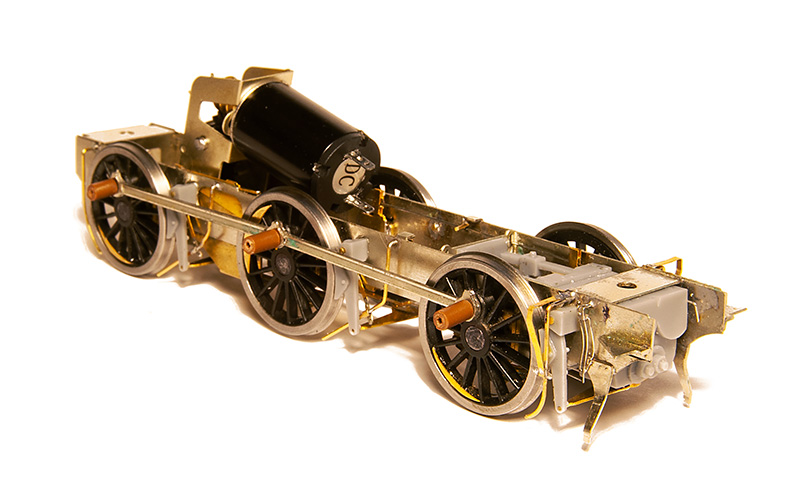

Inside motion modified from the Brassmasters etch. (This is the fifth time I’ve done this now – does it count as an addiction at this point I wonder?) I soldered some small tubes of brass on the chassis side face of the CSB springing plates to give me as much room as i could otherwise the tabs would have been in the way.

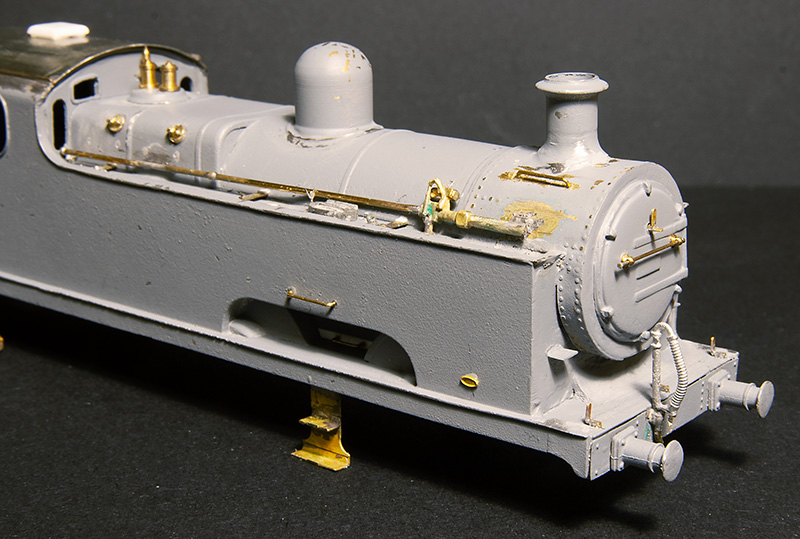

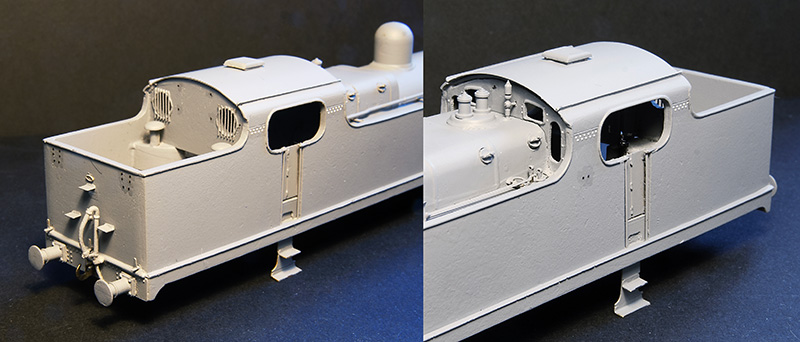

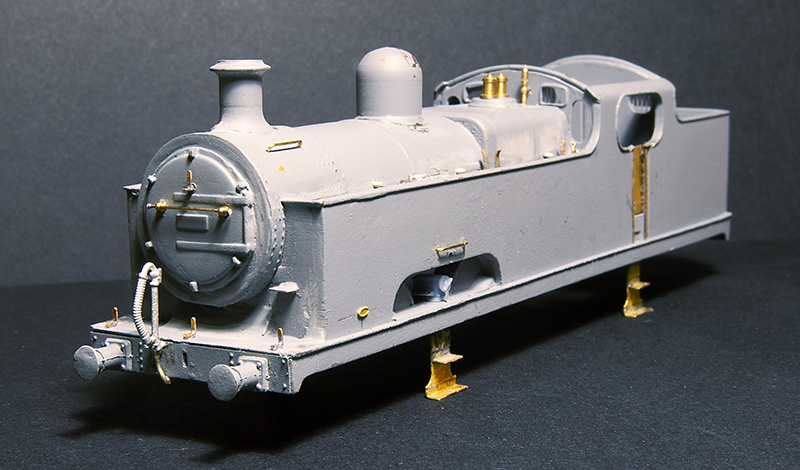

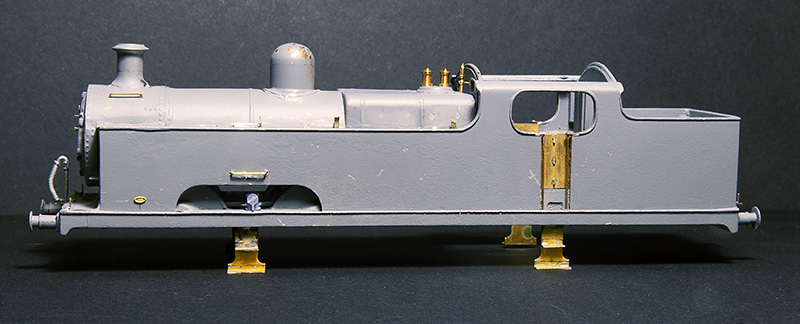

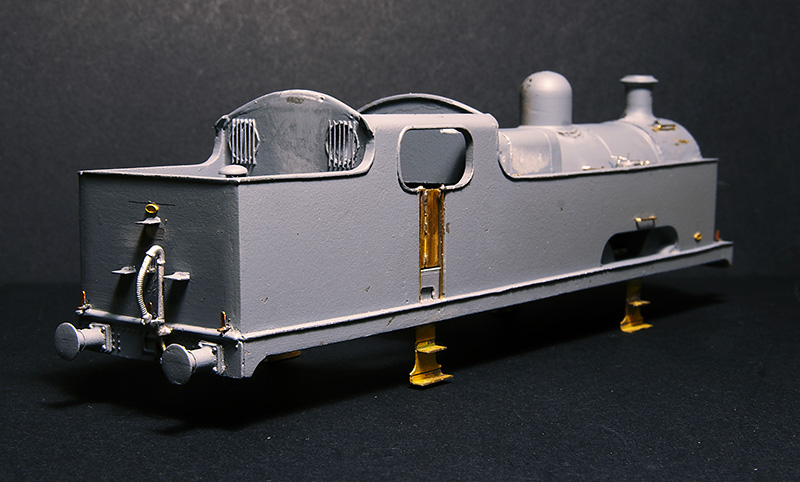

Next stage – – couple of light coats of etching primer. Check for any gaps or rough bits and add any needed rivets -Luckily theres not a lot of them on this class of loco.

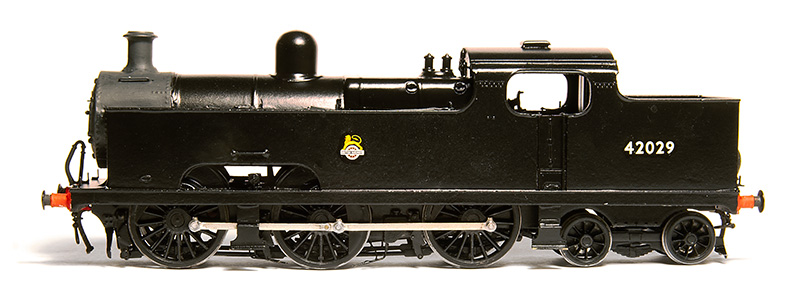

The end result.

These locos really are diminutive – pictured here alongside a 3f

A comparison of the 2 tender sizes.

A comparison of the 2 tender sizes.

Not by any kind of deliberate design I have ended up with quite a little family of Johnson designs now.

Not by any kind of deliberate design I have ended up with quite a little family of Johnson designs now.

Project 2F

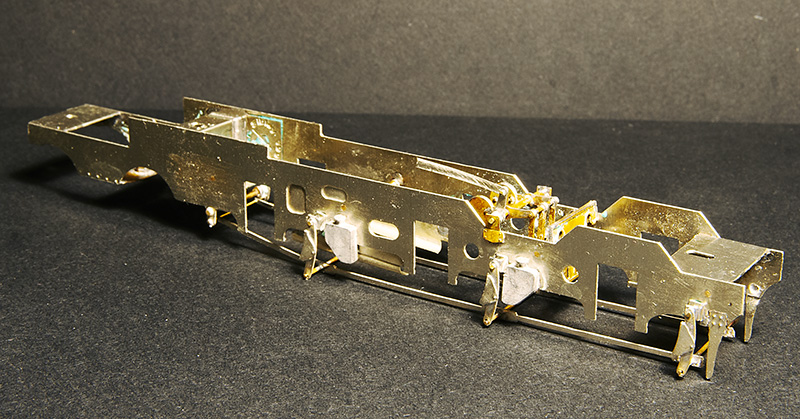

Those who kindly stopped by for a chat at Scalefour Crewe will have seen me fiddling with a set of loco frames. Above is the progress I made over 2 days which to be honest isn’t a lot but that’s a good thing. I always feel that if you get a decent amount of stuff done demoing at a show you’ve kind of missed the point of why you were there!

Those who kindly stopped by for a chat at Scalefour Crewe will have seen me fiddling with a set of loco frames. Above is the progress I made over 2 days which to be honest isn’t a lot but that’s a good thing. I always feel that if you get a decent amount of stuff done demoing at a show you’ve kind of missed the point of why you were there!

The Johnson 2f minefield.

The frames are an old Alan Gibson kit for the Johnson 2f or 1142 class, sometimes referred to as ‘mineral engines’. These and the similar 1357 class are often lumped together as 2Fs but there are a whole ton of differences between locos regardless of the actual class. I recommend a couple of books if you want to go into a lot of detail These being Stephen Summerson’s ‘Midland Railway Locomotives’ Volume 4 and Bob Essery and David Jenkinson’s ‘An Illustrated History of LMS locomotives’ volume 4.

The 1142 class 2fs were built by 4 builders over a 2 year period. Those being Kitson, Dubs, Beyer Peacock and finally Neilson. Initially they were very handsome locos and had a family resemblance with the 700 class Kirtley goods, if you put the laters outside frames to one side. As with all things Midland they were modified over their lives with Belpaire fireboxes and 2 different types of Deeley cab. The lower roof one being the better proportioned of the 2. The class had so many modifications that it’s definitely a case of pick a prototype and model what you see. Some had sandboxes at the outer end of the frames. Some either side of the middle driving wheels. Chimneys were all sorts of different heights too. The main oft’ quoted difference between the 1142 and 1357 classes is the wheel size. the former having 4ft 10in drivers and the latter 5ft 3in. An easy way to tell them apart is the 1142’s had brake linkages outside of the wheels while the 1357’s had them inside. Well most of them did anyway but there are some exceptions to that as well.

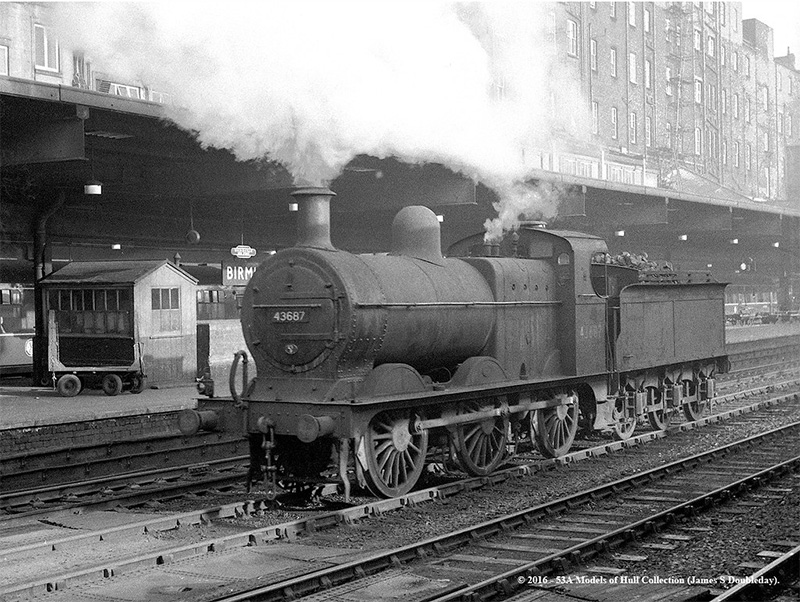

So my intended victim. Pictured here at Harbourne station in 1957. Ive long like the first image due to its run down nature. The station having been closed to passengers in 1934. At the time the picture was taken it was beign used as a wood store for the nearby Chad Valley toy factory. Note also the LMS open stil with its LMS lettering. Both images © 2015 – 53A Models of Hull Collection and used with kind permission.

So my intended victim. Pictured here at Harbourne station in 1957. Ive long like the first image due to its run down nature. The station having been closed to passengers in 1934. At the time the picture was taken it was beign used as a wood store for the nearby Chad Valley toy factory. Note also the LMS open stil with its LMS lettering. Both images © 2015 – 53A Models of Hull Collection and used with kind permission.

58185 was one of the Neilson builds being constructed in 1876 and lasting until 1962 (86 years!). It was originally numbered 1245, then 3013 followed by 23014 before receiving the BR number in 1948.

The Kit

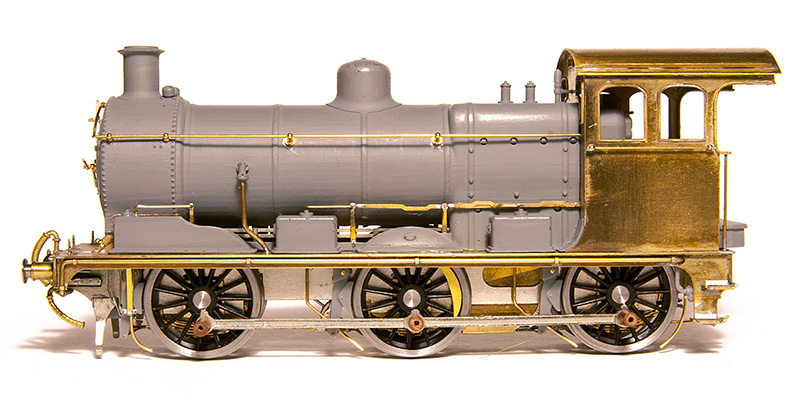

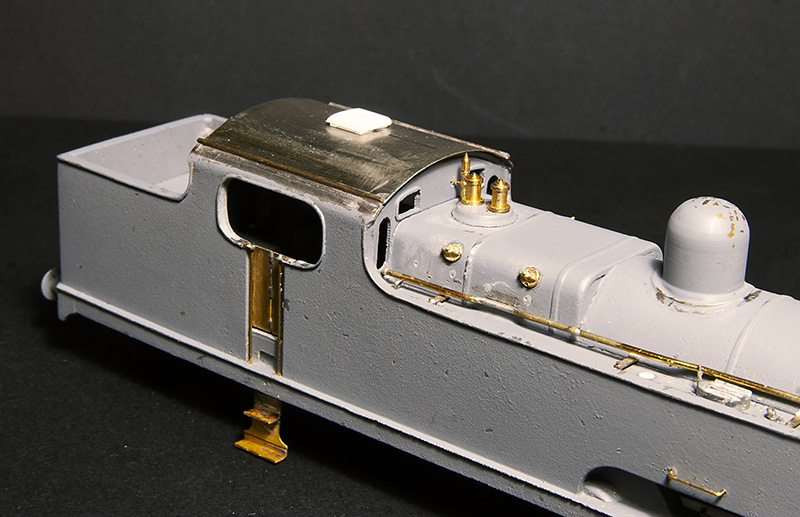

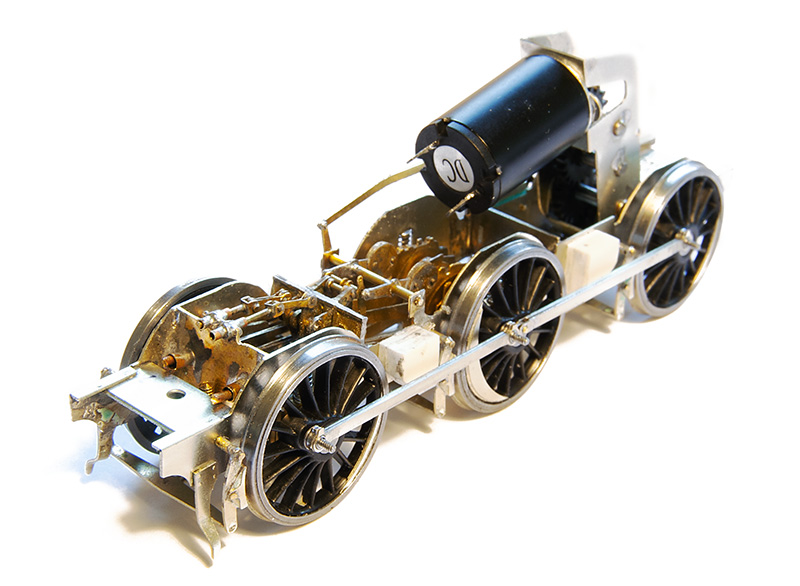

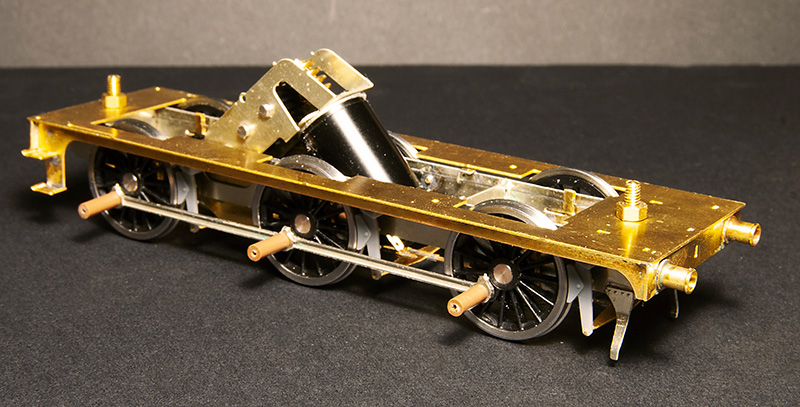

It would be fair to say the Alan Gibson kit is of its time and was probably towards the higher end of kit design when it was released. It doesn’t have any of the slot and tab style niceties we are accustomed to these days though. You can see from the top picture that I used some Alan Gibson frame spacers and drilled the frames for CSB suspension using the info on the CLAG site as a guide (see here)  Progress so far handrails and details next. I found using a High Level Kits road runner plus gearbox with their D1 drive stretcher and a smallish motor I can get the gearbox into the boiler without having to cut into the boiler itself (which was just a bit of brass tube). It’s worth noting that if you want to do the original version London Road models do a kit for it.

Progress so far handrails and details next. I found using a High Level Kits road runner plus gearbox with their D1 drive stretcher and a smallish motor I can get the gearbox into the boiler without having to cut into the boiler itself (which was just a bit of brass tube). It’s worth noting that if you want to do the original version London Road models do a kit for it.

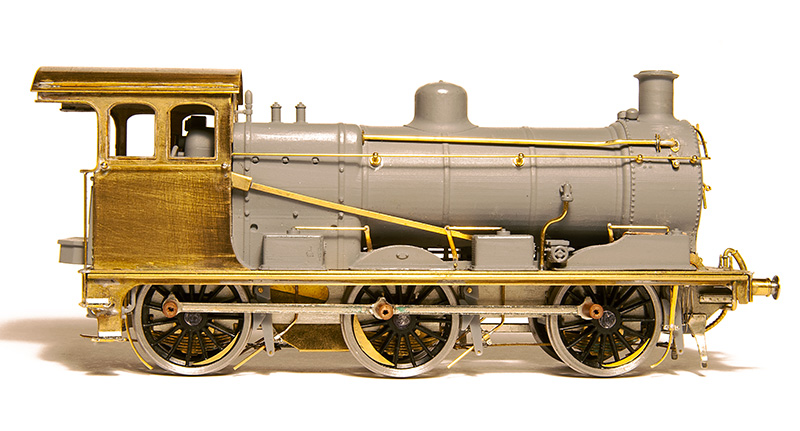

The Johnson tender

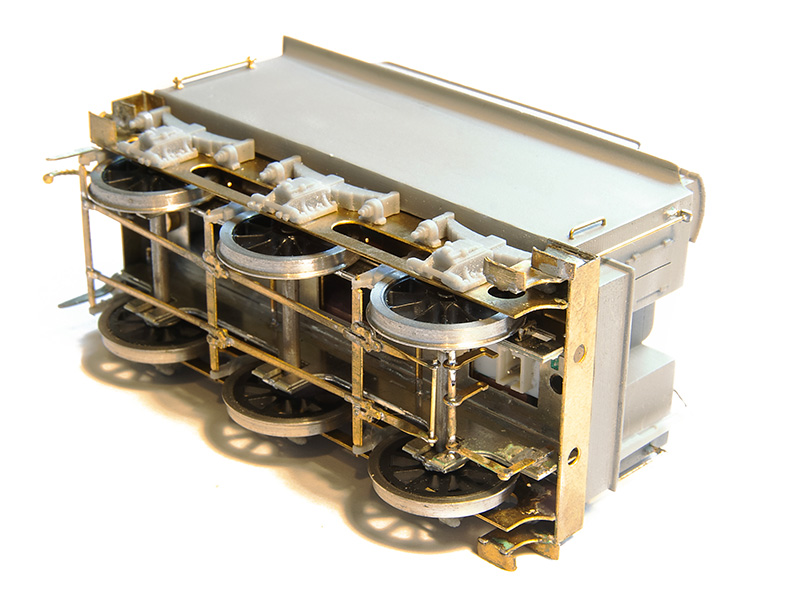

Yes another minefield. These come in a multitude of different sizes. those being 2,350 gallons, 2750, 2950, 3250 and 3500 gallons. Some of the early ones came with springs above or below the footplate and there were were different inner face designs too. My kit came with the 2,350 gallon version but my prototype has the 2,950 gallon version. As the kit as clearly too small a Bachman spare body for the 3,250 gallon one was brought from their spares site. Im far from put off by a bit of plastic bashing.

The Bachmann model is pretty accurate for what it represents. A comparison of the key tank dimensions are (Bachmann/3,250) length – 77mm, width – 28.3mm, height – 16mm. The 2,950 gallon tank is length – 76.3mm, width – 26.1mm, height – 15.6mm. So that differences of 0.7mm, 2.2mm and 0.4mm respectively. I often think it’s a good exercise to think of these number in 2 ways – percentages and relationships. Dealing with percentages first the differences are 0.9%in the length, 8% in the width and 2 and a half% in the height. Its fair to say that the difference in length is all but impossible to see. The height probably not but the width is probably pretty noticeable. That brings me on to relationships. The tender and cab width are the same. If the tender was over a mm wider each side that would definitely look odd. The height as a number is harder to tell but the bottom of the beading lines up with the top of the cabside beading and this relationship is kinda obvious. Some of the class had the larger 3,250 gallon tender and this height is pretty obvious once you are aware of it.

Modellers licence

Some quick measurements showed that dropping the height of the tender by half a mm wouldn’t give the relationship to the cab I was after so I reduced the heigh by 1mm. Yes it means the tender is now a bit too low but the relationship to the cab is better.

The Bachmann tender cut into manageable chunks. The new lower beading is 10×60 though evergreen strip.

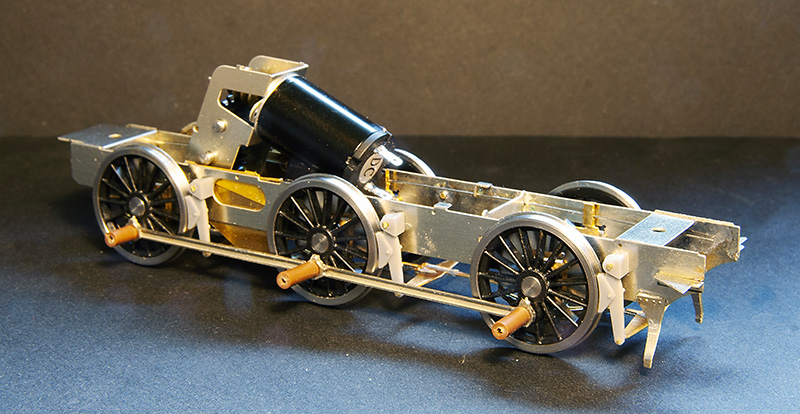

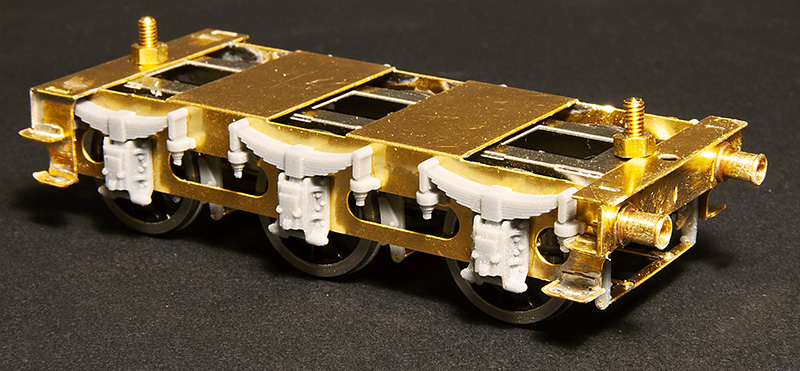

A rough mock up. The inner chassis is Brassmasters from their 3f easychas and the outer frames, brakes and springs are from the Gibson kit. The bufferbeams are also Brassmasters and the buffers are from Lanarkshire models.

A rough mock up. The inner chassis is Brassmasters from their 3f easychas and the outer frames, brakes and springs are from the Gibson kit. The bufferbeams are also Brassmasters and the buffers are from Lanarkshire models.

Progress so far.

Post York show Part 2

Continuing from the last post. I mentioned a revision to the lead in from the cassettes to the layout. Below is a quick video of a bit of a drastic test.

In reality no trains will inter the layout at this speed and aside from the industrial entrance behind the warehouse none of them will be pushed.

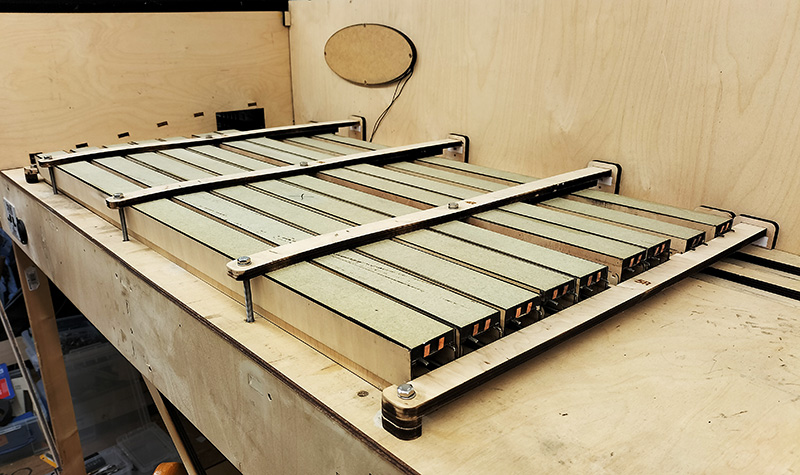

The cassettes are finally done. This is the long ones in their storage position in the station end fiddleyard.

The cassettes are finally done. This is the long ones in their storage position in the station end fiddleyard.

And the DMU and loco ones in the Dudley end fiddleyard. Im not usually one for counting parts but including the 5 connectors on the layout thats a total of 86 ends, 172 springs and just over 6 meters of copper strip. Ive had better projects to do before now!

And the DMU and loco ones in the Dudley end fiddleyard. Im not usually one for counting parts but including the 5 connectors on the layout thats a total of 86 ends, 172 springs and just over 6 meters of copper strip. Ive had better projects to do before now!

On to the tweaks on the layout itself. Just a few of these. Those at the show may have seen the odd derailment of stuff coming into the Stourbridge platform. The Derby lightweight seeming particularly susceptible to this. Turns out the barrow crossing on the left hand rail has become loose and was higher than the rail head. The crossing on the Dudley line was also a tad high but not loose so I’ve removed both to get a better fit. The Derby lightweight will be checked too to see if theres any problems on the stock side.

On to the tweaks on the layout itself. Just a few of these. Those at the show may have seen the odd derailment of stuff coming into the Stourbridge platform. The Derby lightweight seeming particularly susceptible to this. Turns out the barrow crossing on the left hand rail has become loose and was higher than the rail head. The crossing on the Dudley line was also a tad high but not loose so I’ve removed both to get a better fit. The Derby lightweight will be checked too to see if theres any problems on the stock side.

I noticed when cleaning the track that one of the smaller sections of track on the threeway was a little low. I don’t recall anything coming off on this particular bit but I’ve fixed it anyway. There were a few tight spots that have been amended too. My mint block would go through but with a bit more resistance than I liked. One of the tight spots was between the running rail and the check rail. Just need to put new half chairs in place and cosmetic fishplates. Then paint the rail and blend it all back in.

I noticed when cleaning the track that one of the smaller sections of track on the threeway was a little low. I don’t recall anything coming off on this particular bit but I’ve fixed it anyway. There were a few tight spots that have been amended too. My mint block would go through but with a bit more resistance than I liked. One of the tight spots was between the running rail and the check rail. Just need to put new half chairs in place and cosmetic fishplates. Then paint the rail and blend it all back in.

Finally the check rail coming in to the yard was originally an after thought on normal flexi-track. It wasn’t as neat as it could have been and being normal track there was no gauge widening on what it the tightest curve on the layout. The far rail was removed with the moulded chairs smoothed away and the rail replaced with proper check rail chairs.

Finally the check rail coming in to the yard was originally an after thought on normal flexi-track. It wasn’t as neat as it could have been and being normal track there was no gauge widening on what it the tightest curve on the layout. The far rail was removed with the moulded chairs smoothed away and the rail replaced with proper check rail chairs.

York show post-mortem

Over the Easter weekend Brettel Road headed north 3 hours to the York MRC exhibition.

Despite a minor cardiac event at 5pm on the Thursday evening when it looked like the van may not be available due to a medical emergency set up went smoothly. Little did I know what was to come over the next 3 days.

We had problems! The biggie was that the cassettes were still not reliable, to the point where they were the worst they have ever been. Despite this the guys battled on against the layout that was absolutely determined to fight us ever step of the way (thanks again chaps). There was a problem with the main point into the yard behind the station which I did manage to patch up on the Saturday afternoon and the track in the yard under the bridge (of course it was!) had become damaged. Something we didn’t notice until a member of the public kindly let us know. The whole show was a mixture of frustration and some degree of embarrassment really that the layout was performing as smoothly as the proverbial bag of nails. Despite all this we did still attract a lot of interest throughout the 3 days and many kind compliments were received along with 4 or possibly 5 requests to take it out to more shows so I guess from the public side of the barrier it didn’t seem quite as disastrous as it did to me. Thanks to the guys at York MRC for having us and looking after us so well. The elements of the weekend that didn’t involve the layout were great!

Diagnosing the problem

The problem with the cassettes was two fold and wasn’t something we could really address at the show. Brettell Road actually has 45 cassettes in total in 3 different sizes.

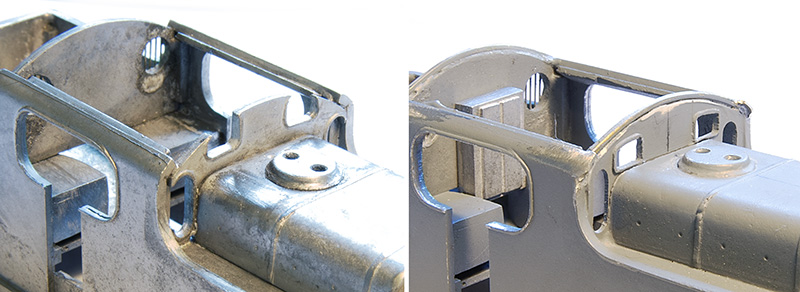

When I built and tested them originally, I tested them for resistance using the buzzer in my volt meter. What I didn’t test was if there was any voltage drop or not. On the left are 3 loco cassettes of the design we had at York showing a voltage drop of over 5 and a half volts or as good as 40%! Little wonder it caused us grief. On the right a revised design tested on 3 cassettes with no loss of volts at all.

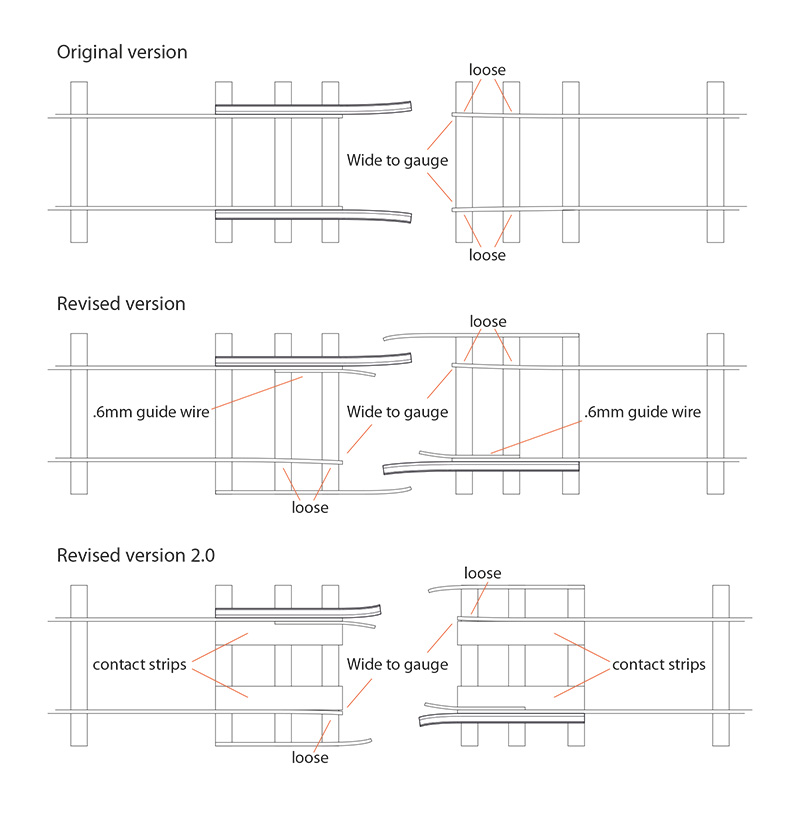

When I built and tested them originally, I tested them for resistance using the buzzer in my volt meter. What I didn’t test was if there was any voltage drop or not. On the left are 3 loco cassettes of the design we had at York showing a voltage drop of over 5 and a half volts or as good as 40%! Little wonder it caused us grief. On the right a revised design tested on 3 cassettes with no loss of volts at all.  A little diagram of my cassette evolution. The top design is what I used on the short version of the layout and that seemed to work fine. As these cassettes were single ended I also fitted a light to them so that we could see that they were electrically connected.

A little diagram of my cassette evolution. The top design is what I used on the short version of the layout and that seemed to work fine. As these cassettes were single ended I also fitted a light to them so that we could see that they were electrically connected.

With version 2 I wanted them to be double ended and introduced the idea of smaller loco cassettes. This had 2 effects. While on version 1 the rails were squeezed tightly by the guide rails on the revised version the fit was less positive. The second effect is a loco cassette doubles the number of connections. If everything is really clean they work just fine however in the real word things don’t stay really clean for long. Because of the design, the bits I needed to keep clean were hard to get to and the sort of area what would naturally collect dirt and crud. The loose stock rails were also still prone to go the wrong side of the guide wire and I found many had failed at the soldered joint on the third sleeper in exaggerating the problem. I guess my absolute minimal solder approach I use when building kits isn’t such a good idea in this application.

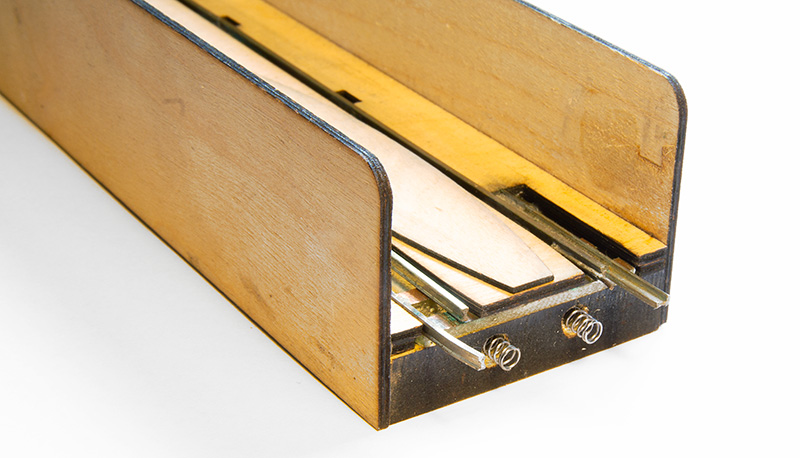

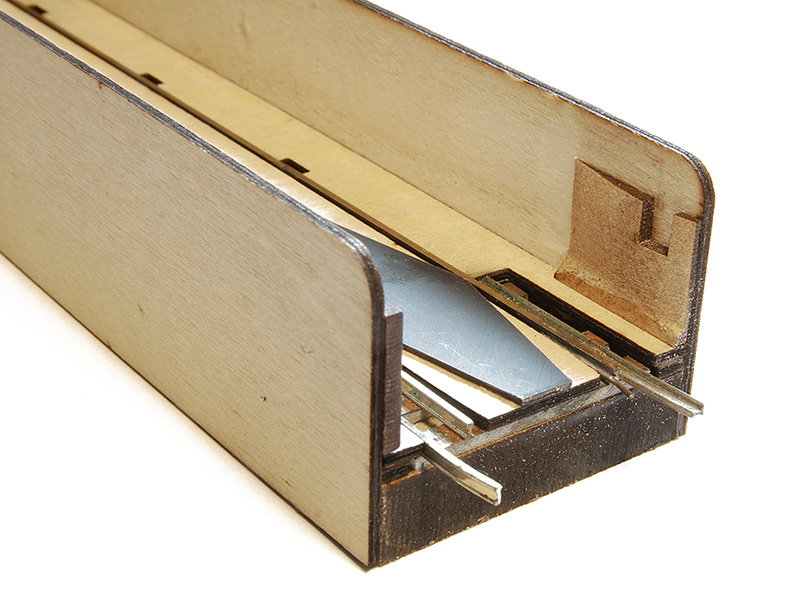

The solution is to add contact strips from 0.2mm thick, 5mm wide copper that fold down the front giving a much bigger contact area that, just as importantly is easier to get to to keep clean. I also reduced the length of the rails that stick out and soldered the loose rail to an extra sleeper so it doesn’t move as much. The cassettes are kept in compression when on the layout by a simple peg (actually cheap, small screwdrivers) fitted into holes drilled into the baseboards.

Now this is a bit belt and braces but on an exhibition layout thats never a bad thing. Rather than just rely on the springiness of the copper strips I drilled holes behind them and fitted a couple of spring (actually springs from smiths coupling hooks that id been saving for some unknown reason).

Now this is a bit belt and braces but on an exhibition layout thats never a bad thing. Rather than just rely on the springiness of the copper strips I drilled holes behind them and fitted a couple of spring (actually springs from smiths coupling hooks that id been saving for some unknown reason).

Before and after. The little side parts that hole the cassette ‘buffer stops’ were still causing problems so I’ve decided to remove them completely and redesign the stops.

I also took the opportunity to move the cassettes back a little and extend the lead in roads as we were having derailments coming onto the layout at both ends. This may have been the cassettes or it may have been something else. Originally I had check rails here but tests of the new sections without them is making me think they were unnecessary.

I also took the opportunity to move the cassettes back a little and extend the lead in roads as we were having derailments coming onto the layout at both ends. This may have been the cassettes or it may have been something else. Originally I had check rails here but tests of the new sections without them is making me think they were unnecessary.

Pre-show tweaks.

Been doing some final pre show tweaks before Brettell Road heads off to York in a little over a week.

After the last show (nearly a year ago now) there was a little bit of damage picked up. Nothing too major and the kind of job that I intend to get around to at some point but then don’t. Case in point this but of fence which got squished.  While working on this area I took the opportunity to add some rudimentary steps to the signal box. Something I meant to do at the start but didn’t. I had put the gate in but the poor signaller would break his leg falling off the edge of the platform! There was also a platform light that got bent and thats been repaired and replanted.

While working on this area I took the opportunity to add some rudimentary steps to the signal box. Something I meant to do at the start but didn’t. I had put the gate in but the poor signaller would break his leg falling off the edge of the platform! There was also a platform light that got bent and thats been repaired and replanted.

Something else that got bashed but didn’t actually break is the chimney on the platform shelter. This has very little clearance to the other board when packed up so rather than wait for it to get smushed I decided to make it removable. A few magnets popped into holes and a bit of steel on the roof and hopefully thats a problem averted. I also decided that the roof was a bit too vanilla for a building due to be closed in a week so I’ve had a look at this area too.

Something else that got bashed but didn’t actually break is the chimney on the platform shelter. This has very little clearance to the other board when packed up so rather than wait for it to get smushed I decided to make it removable. A few magnets popped into holes and a bit of steel on the roof and hopefully thats a problem averted. I also decided that the roof was a bit too vanilla for a building due to be closed in a week so I’ve had a look at this area too.  You may remember i talked about distress paint before when I was building the signal box and I’ve used it again here. For some reason it didn’t really crinkle up this time so a wash of Tamiya extra thin cement was painted on to add some more wear and tear. The mossy deposits are AK Interactive dark and light slime with some of their moss deposits.

You may remember i talked about distress paint before when I was building the signal box and I’ve used it again here. For some reason it didn’t really crinkle up this time so a wash of Tamiya extra thin cement was painted on to add some more wear and tear. The mossy deposits are AK Interactive dark and light slime with some of their moss deposits.

Next is track cleaning and hoovering before packing the boards away, then the joy that is cleaning wheels!

In an uncharacteristic fit of tidiness I’ve made a proper box for the road vehicles, removable chimneys and coupling poles. When I say ‘made’ I mean got a box off ebay for around a tenner and stuck some foam in it!

In an uncharacteristic fit of tidiness I’ve made a proper box for the road vehicles, removable chimneys and coupling poles. When I say ‘made’ I mean got a box off ebay for around a tenner and stuck some foam in it!

The saddle mounted tank I featured last time is done and tested.  Finally Railcar W14 waits for the road. The cats are undisturbed by its presence.

Finally Railcar W14 waits for the road. The cats are undisturbed by its presence.

Info on the York show. Please say hi if you are going.

A trio of tanks.

A trio of tanks this time starting with… … the LMS milk tank I featured last time. Now ready for service.

… the LMS milk tank I featured last time. Now ready for service.

The Bachmann 14t cradle mounted tank wagon. Very much of its time with a very generic (and pretty rubbish if I’m honest) chassis.

Luckily Justin does something a little more refined and very nice to build it is too.

Ready for the brass bits to be painted. The ladder is only loosely in place. The walkway is from my box of useful stuff (I think Stenson models) and the buffers are from Lanarkshire Models.

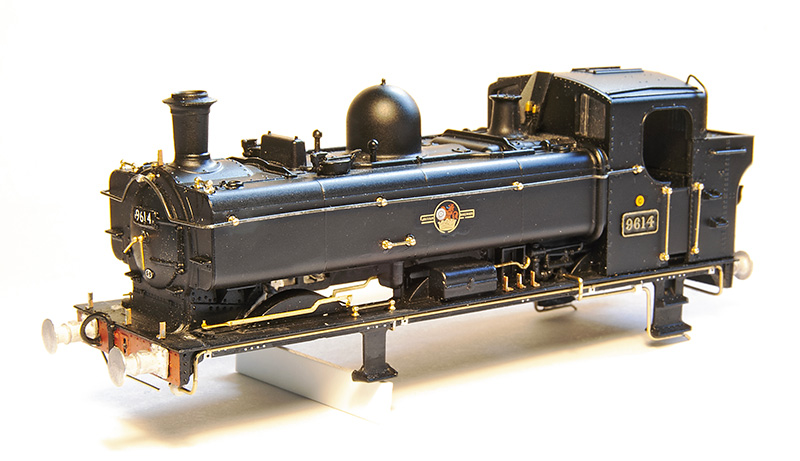

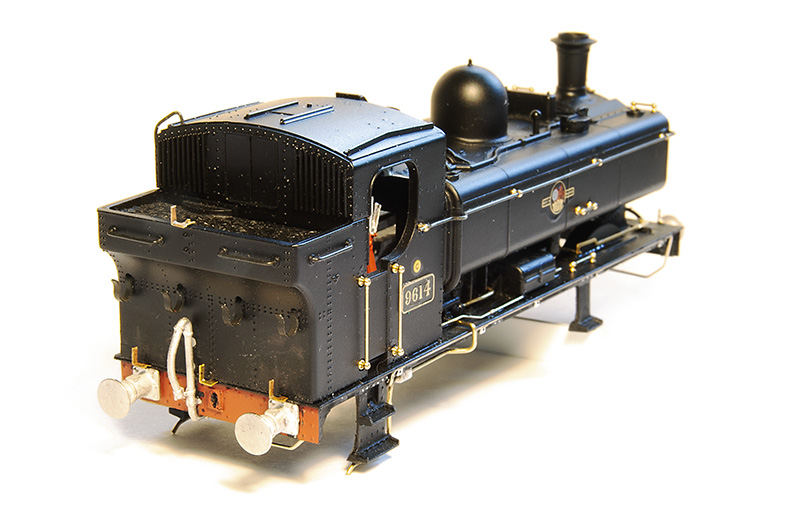

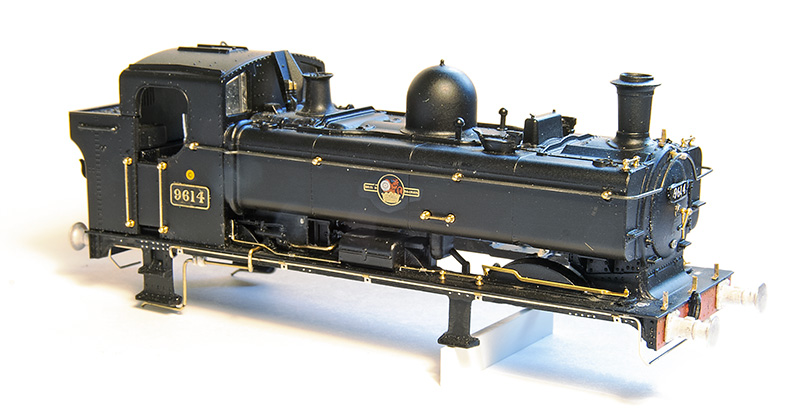

Still sticking with the theme of tanks but is a slightly dubious way, work in progress on a 96xx tank. I originally picked this up quite cheaply with and idea to include it in my scrap train. Round Oak scrapped quite a few locos, but it didn’t take me long to decide to do it as a working loco instead. Especially as a picture of this very loco heading a freight train through Brettell Lane cropped up in my facebook feed.

As far as I can tell this model by Bachmann is an evolution of the Mainline model I’ve already used to do my 57xx tank, with a later cab and other refinements. All of the handrails are separately fitted but I felt the handrail knobs were way too big so I replaced them with Alan Gibson ones. I reused the long handrail but as its not so wide i had to cut it in half to lose a little from the middle. The sandbox fillers are too far forward as they were repositioned with RT Models linkages but not before the front splasher was cut down in height. A compromise for the over sized flanges on the RTR wheels and something that has entered my ‘now I’ve seen it, i cant unsee it’ mindset when looking at model steam locos. Smoke box dart is also Gibson and the lamp irons are from Masokits. I also replaced the pipes on the footplate. Some 96xx had a bracket half way along with i quite liked but unfortunately 9614 was one that didn’t.

Rear view. The lamp irons were too high up on the bunker. This is correct for a 57xx but on the 96xx tanks they were lower. I was replacing them anyway. Buffers are Lanarkshire models. I prefer a better detailed solid buffer over a less detailed sprung one.

Rear view. The lamp irons were too high up on the bunker. This is correct for a 57xx but on the 96xx tanks they were lower. I was replacing them anyway. Buffers are Lanarkshire models. I prefer a better detailed solid buffer over a less detailed sprung one.

Drivers side. The pipework just in front of the cab is the same on both sides of the model. Again OK for a 57xx but on the 96xx they were different with a somewhat more barren look on this side. The footplate pipework is also routed differently around the cab footsteps. Chassis will be a high level one with my working inside motion bodge as described here. https://p4newstreet.com/an-unremarkable-little-tank-engine-part-1/

Finally something that you will never see – Brettell road in the sun! It was coming in the shed door and caught my attention.

Finally something that you will never see – Brettell road in the sun! It was coming in the shed door and caught my attention.

return to milk tanks

My history with milk tanks has been, to an extent unnecessarily convoluted. Originally I planned to build a David Geen kit for a midland one and I got the Rumney Models underframe for it in preparation. However when I came to get the kit from David he only had one left and that was for a GWR one. Justin kindly swapped the chassis kit for me and, as I’ve mentioned before, doing battle with my collection of bits I ended up with my model of a milk tank.

However the desire for at least one LMS one never went away and for more years than it really should have been I would discuss the idea of doing one using Rumney bits with a Lima tank when I saw Justin at a show. Apparently I wasn’t the only one

Well finally, heres what I’ve come up with, The only bits of the Lima one left are the tank – end supports and filler hatch. The rest is pretty much all Justin with buffers from Lanarkshire models and the tank supports kindly cut for me by Tim Horn.

The diagonal bracing is obviously over-length at the moment. The strapping isn’t tight and the ladder is just rested in position until after painting. This seemed much less of a fight than my other one, so much so that I’ve ordered bits to do another 2.

A batch of good old Airfix kits

I recently picked up a batch of good old Airfix wagon kits. There were 4 brake vans, a 35t tank, a 16t mineral wagon and a cattle van. Of those one of the brake vans was finished and another one along with the 16t mineral were semi completed. I really wanted the brake vans as I had identified a need for more BR ones and more that were fitted as up until now I didn’t have any at all, just a couple of piped ones.

Note to self – if you’re going to batch build some wagons don’t pick ones that have loads of different sized handrails!

Note to self – if you’re going to batch build some wagons don’t pick ones that have loads of different sized handrails!

The first 2. A piped one and a fitted one, both built with Bill Bedford W irons, Rumney models springs and axleboxes and additional details.

The first 2. A piped one and a fitted one, both built with Bill Bedford W irons, Rumney models springs and axleboxes and additional details.  This one is a BR build of the LNER design note the shorter steps, no end handrails and different lamp irons. Build was the same as the first 2.

This one is a BR build of the LNER design note the shorter steps, no end handrails and different lamp irons. Build was the same as the first 2.

This was the last one and the one that was already built. I replaced the handrails and roof and added the same details as the other 3. This one is unsprung.

On to the tank wagon. Not one this done before. This is sprung with Bill Bedford W irons. As supplied the solebars are too shallow so I carefully cut the top rib off flush with the face and added a new top rib from microstrip. Buffers are from my draw of buffers and I think they may be from A1 models. RT models do a nice little etch for these and while the ladder supplied is really nicely done it is a flat etch so I replaced them with ones from Rumney models. I replaced the brake gear with bits from the spares box.

The finished wagon. Transfers are from Cambridge Custom Transfers.

Flights of Fancy – Part 2

I ended the first part of this project by mentioning I needed some bits from Scaleforum. One of these was the injector which I modified a little from an Alan Gibson one.

I ended the first part of this project by mentioning I needed some bits from Scaleforum. One of these was the injector which I modified a little from an Alan Gibson one.  I also needed some firebox wash out plugs. Again Alan Gibson did the honours. It’s worth noting that they are not on the same places either side. The cab roof was just a bit of nickel silver rolled to the right radius and a few bits of strip for the rainstrips. The vent was filed up from Evergreen section. While on the subject of the cab the kit includes some bits and an etched floor. I found the handbrake column, if mounted to the cab floor as the kit was designed, gets in the way when trying to mate the body and chassis together so I cut it from the floor and mounted it to the body instead. The kit specifies that the reversing screw is mounted on the left side of the cab but, while hard to see in photos, it seems to be mounted to the right side so thats what I did.

I also needed some firebox wash out plugs. Again Alan Gibson did the honours. It’s worth noting that they are not on the same places either side. The cab roof was just a bit of nickel silver rolled to the right radius and a few bits of strip for the rainstrips. The vent was filed up from Evergreen section. While on the subject of the cab the kit includes some bits and an etched floor. I found the handbrake column, if mounted to the cab floor as the kit was designed, gets in the way when trying to mate the body and chassis together so I cut it from the floor and mounted it to the body instead. The kit specifies that the reversing screw is mounted on the left side of the cab but, while hard to see in photos, it seems to be mounted to the right side so thats what I did.

With everything in place and being happy wit the fit of things the body was given another light undercoat before the missing rivets were added from my dwindling supply of Archers along with some from Railtec. Thankfully the flatirons dot have a lot of visible rivets.

With everything in place and being happy wit the fit of things the body was given another light undercoat before the missing rivets were added from my dwindling supply of Archers along with some from Railtec. Thankfully the flatirons dot have a lot of visible rivets.

I don’t normally take a painted but pre-weathered picture but this time I made an exception. I mentioned in the last post that because of the carzatti front axle the coupling rods seemed backwards to the norm with the joint ahead of the middle axle not behind it. When No.2000 was modified this remained the case. The kit has the coupling rods the normal way round with the joint behind the middle axle and I’ve never seen a model flatiron (in either 4mm scale of 7mm scale) that addresses this. I found 52f models do a set that have the right wheelbase with the joint in the right place so I used those instead. One little tip that seems really obvious but I’ve never seen anyone mention (perhaps its because it is obvious to everyone else?) is that I line up the coupling rod on this side with the orientation of the grub screw on the final drive gear. It makes accessing the grub screw simple should you need to in the future as you know where to stop the wheels rotation.

I don’t normally take a painted but pre-weathered picture but this time I made an exception. I mentioned in the last post that because of the carzatti front axle the coupling rods seemed backwards to the norm with the joint ahead of the middle axle not behind it. When No.2000 was modified this remained the case. The kit has the coupling rods the normal way round with the joint behind the middle axle and I’ve never seen a model flatiron (in either 4mm scale of 7mm scale) that addresses this. I found 52f models do a set that have the right wheelbase with the joint in the right place so I used those instead. One little tip that seems really obvious but I’ve never seen anyone mention (perhaps its because it is obvious to everyone else?) is that I line up the coupling rod on this side with the orientation of the grub screw on the final drive gear. It makes accessing the grub screw simple should you need to in the future as you know where to stop the wheels rotation.

Below some pictures of the finished loco with my usual caveat of still needing coal and a crew.

With her baby sister!

With her baby sister!

Flights of Fancy – Part 1

Long time readers may remember this illustration I did a fair few years ago. At the time I was toying with the idea of BR Flatiron for Brettell Road. People who know anything about these locos will know that they only made it as far as 1938 before the lastof them went for scrap but my theory was what if they didn’t and made it another 2o years or so? After all we are all happy to bend the historical truth when it comes to places but why not locos too?

A brief history

Samuel Johnson of the Midland Railway had identified a need for a large passenger tank engine in 1903 and while a 0-6-4 seemed a logical progression of their 0-4-4 tanks several ideas and arrangements were put forward both before and after the design by Deeley was settled on. These ranged from a 4-4-4, a 2-6-2 with odd split side tanks, through several variations of outside cylindered 2-6-4’s and a 4-6-4. All of the class of 40 were built in 1907. As it turned out this was not a wheel arrangement that would become at all common in the UK. The front axle was mounted into a Carzatti slide giving extra play and resulting in a somewhat backwards arrangement of coupling rod with the knuckle joint ahead of the middle axle and not behind it as was the norm.

In early LMS days the class were fitted wit new superheated Belpair boilers resulting in a different firebox and being longer, the boiler now sticking out from the front of the tanks. The cab spectacle plates were also changed at the same time.

In 1928 loco No.2015 derailed at speed near Newark and a passenger on its train was killed. 2 more derailments occurred in early 1935. The first instance was when N0.2023 derailed at Ashton under Hill in February, killing its driver. 3 weeks later number 2011 was observed by railway inspectors operating between Leicester and Burton upon Trent only to itself derail 5 days later at Moira. Fortunately this time no serious injuries occurred. But the reputation had set in, the class were well known as rough riders on anything other than perfect track and were noted to run smoother going backwards.

An idea not completely without precedent.

The case for these locos lasting longer than they did is not without precedent. Class leader N0.2000 underwent some modifications to see if the riding could be improved. These were the replacement of the front axle arrangement with traditional springs (giving a different look) and an improved bogie with side bolsters. No 2000 was tested against an unmodified classmate No.2012 which itself had recent general repairs and not yet clocked up 1000 miles since. Both locos were considered to be in first class running order.

On the first test No.2000 ran between 35 and 50 mph before selling back to 35 and it was reported that the engine rode very steadily with no side movement reported of the trailing bogie. Test 2 saw No.2000 run between 45 and 50mph settling back to 45 with the same results. Test 3 was run at 55 and occasionally 60mph and this test was satisfactory enough to try test 4 where she was run over 60mph, reaching a speed of 67 before selling back to 65. It was reported that a slight amount of side oscillation developed and a slight roll but was still considered satisfactory riding.

No.2012 ran 3 tests. Test 1, 35mph occasionally touching 40 and the riding was reported as good with a slight oscillation and roll being perceptible on the footplate. Test 2 saw 45mph with occasional 47 and the riding was considered fairly good but with more oscillation and tendency to roll. The final test saw running at 55mph with occasional 60 and the riding was reported as rough with the oscillation and roll said to be pronounced and the front end having a tendency to develop an up and down surging motion.

Although the results of the modifications to No.2000 were good Stanier decided that the rest of the class were not worth altering and between 1935 and 1938 they were all scrapped with many of the (standard) parts going on to other locos. It was reported that many of the boilers were used on 4f’s.

But what if Sanier thought the modification were worth doing to the entire class? They were only 30 years old and many midland locos lasted much longer than that. As the boilers went to other locos they were obviously good so it it such a leap to think that a modified flatiron could indeed make it into BR days with only a slight tweak of history is it?

The Model

Luckily for us South Eastern Finecast do a kit for these loco’s and I’ve had one in the stash pretty much since I did the drawing above.

Starting with the bogie as supplied on the left and my modified version on the right. It’s been modified mechanically to provide basic springing on all 4 wheels and a basic form of sprung side control. As supplied the bogie is designed to be attached to a swinging arm much like the RTR guys tend to do. I didn’t really like that idea much if I’m honest.

The main frames modified with some spare Brassmasters inside motion bits. I considered there was no way you would be able to see working inside motion so just modelled the bits I felt you might see if you looked hard enough!

The main frames modified with some spare Brassmasters inside motion bits. I considered there was no way you would be able to see working inside motion so just modelled the bits I felt you might see if you looked hard enough!

The cab Spectacle plate is a particularity weak point of the kit as it bears only a passing resemblance to the real thing, I made a new one from plasticard as can be seen on the right. If anyone wants the drawing for this (which I admit is a best guess on my part) it can be downloaded from here. The rebuilt cabs also seemed to have slightly longer roofs than the originals and little bits of Nickel strip were soldered to the corners to replicate this.  Front view. The kit relied on an upper half of the boiler/smokebox merging with the lower half which is cast as part of the tank front and this forming the front of the smokebox. The end result wasn’t all that round so I cut it back and used a 22mm copper ring in its place Buffers are from Lanarkshire Models and lamp irons from Stenson Models

Front view. The kit relied on an upper half of the boiler/smokebox merging with the lower half which is cast as part of the tank front and this forming the front of the smokebox. The end result wasn’t all that round so I cut it back and used a 22mm copper ring in its place Buffers are from Lanarkshire Models and lamp irons from Stenson Models

The rear view. The steps are cast into the rear of the bunker and where a little chunky. Also the top one was too low so these were replaced with some of my mk1 coach end steps. The window frames are from a Mainly Trains spectacle plate etch. Note the larger buffers on this end.

The rear view. The steps are cast into the rear of the bunker and where a little chunky. Also the top one was too low so these were replaced with some of my mk1 coach end steps. The window frames are from a Mainly Trains spectacle plate etch. Note the larger buffers on this end.  The top of the tanks are vague as supplied with just casting for the water filer caps and 2 air vents that were related to the water pick up gear. In reality only 2015 had this fitted so they should be left off all other models of the class. This is my educated guess of what should be there but i do think there should be more clutter than this. Photos of this area are rare and so far I’ve only found 2

The top of the tanks are vague as supplied with just casting for the water filer caps and 2 air vents that were related to the water pick up gear. In reality only 2015 had this fitted so they should be left off all other models of the class. This is my educated guess of what should be there but i do think there should be more clutter than this. Photos of this area are rare and so far I’ve only found 2

Progress will now need to wait until after Scaleforum where i need some more bits.

Its all gone a bit Eastern Region – Part 2

Earlier in the year I showed progress on a test build of the Brassmasters J17 kit test build. What follows is progress since then.

To be fair there wasn’t a huge amount left to do as I left it. One of the jobs was the business end of the brake gear on both the loco and tender.

The other little job on the tender was the guard irons which had been missed off the test etch. These were fashioned up from scrap using a scaled image of the production etch as a guide.

The other little job on the tender was the guard irons which had been missed off the test etch. These were fashioned up from scrap using a scaled image of the production etch as a guide.

When I showed the side on view before I had managed to get the sanding linkages all wrong. This was subsequently corrected.

(Video © Tim Horn and used with permission) Then it was off to Tim’s for a few days work blocking in the basic greenery on North Elmham which was also an ideal opportunity to give the J17 a chance to stretch its legs. It was unweighted at this point except for a few pound coins in the tender. Attention then switched to getting Brettell Road ready for Scalefour Crewe and besides I thought it would be good for the loco to be displayed on the Brassmasters stand in the raw so to speak. However since then it’s now been finished off with the exception of a crew and some coal in the tender.

For part one of this little project click here

Post Scalefour Crewe reflection

Scalefour Crewe was an excellent show in my opinion and feedback from my operators was that they all enjoyed themselves (thanks for your help guys). Thanks to the show organisers for inviting us. The layout seemed well received and many people were kind enough to say nice things about it. We seemed to be quite successful in holding people attention throughout the weekend.

As with any outing theres aways a period of reflection on how the show went. The layout seemed to fight us a little in the morning but settled down. The main issue being the cassettes were causing a few problems.

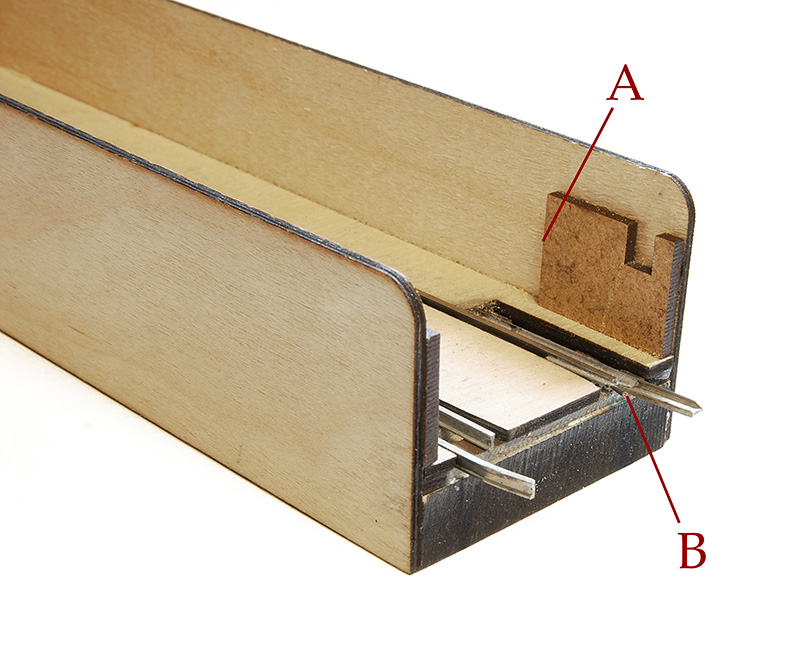

There were 2 areas with the cassettes that need addressing. Area A is that any stock that wasn’t on the rails would strike the edge of the end stop supports and bring the whole train to a halt. It’s unrealistic to think that everything on a cassette will always be on the track 100% of the time as the cassettes are moved around. Thats the point of them after all.

There were 2 areas with the cassettes that need addressing. Area A is that any stock that wasn’t on the rails would strike the edge of the end stop supports and bring the whole train to a halt. It’s unrealistic to think that everything on a cassette will always be on the track 100% of the time as the cassettes are moved around. Thats the point of them after all.

Area B is an easy fix. Theres a bit of wire that holds the connecting rail (which is loose at the end) in line with the rail on the cassette and agains the guide rail. These bits of wire were too straight meaning the joining rail could go the wrong side and all the stock would fall off. A little more of an angle to the wire will solve that.

First approach to fix problem A was to shape the end supports so that stock doesn’t stop when it hits it. A few trials showed this to be effective but it merely gets the stock past the ends and it still stays off the track. Plan b was to make a re-railer from 30 thou plasticard so that any errant stock is pushed back on to the track. The advantage of this is that I don’t need to reshape the end supports at all as the stock is on the track as it runs off the cassette. This is just a rough proof of concept of course but if I fit one to the end of every cassette, as wagons will need to run of their own cassette and through the loco cassette that gives 3 opportunities to re-rail any rogue wagons and if they are still off after all that then they deserve to go back in the box for attention back home!

First approach to fix problem A was to shape the end supports so that stock doesn’t stop when it hits it. A few trials showed this to be effective but it merely gets the stock past the ends and it still stays off the track. Plan b was to make a re-railer from 30 thou plasticard so that any errant stock is pushed back on to the track. The advantage of this is that I don’t need to reshape the end supports at all as the stock is on the track as it runs off the cassette. This is just a rough proof of concept of course but if I fit one to the end of every cassette, as wagons will need to run of their own cassette and through the loco cassette that gives 3 opportunities to re-rail any rogue wagons and if they are still off after all that then they deserve to go back in the box for attention back home!

Above is a little test video. The brake van is running along the edge of the cassette before the join.

Aside from the usual small stock of wagons that need attention either through failures or just a general refusal on their part to play nicely we had a few issues taking stuff in and out of the yard. There were also a few clunks when running through the slip which is a dead giveaway that something is not quite right somewhere. So on returning home and when I had just 2 boards up, allowing me better access to the slip this has been investigated, tweaked and one of the check rails replaced.

A Bachmann brake van (straight wheel swap, no compensation) does the testing.

Artistic licence

This weekend I was helping Tim at Railex (helping in the loosest term – I was there anyway!) and had a very interesting chat with a chap about lighting on layouts. He explained that lighting is what he does and he was obviously somewhat of an authority on the subject.

Anyway the subject of this image came up, Apologies for posting it again, I get people are probably sick of seeing it but I have added a bit of rain as some people asked for it. He explained that sodium lighting on a scale of colour gives a very high spike in the yellow range and doesn’t output any other colours. For this image to have the colours it does it would need a white light source, I cant say its the moon because its raining! It actually does have a white light source as I have a string of dim-able LEDs on the wall of the shed that I use to infill my night pictures. He very obviously knew exactly what he was on about! People may have noticed that at night we sometimes see in black and white. It was something I was already aware about on a very basic level. Cameras are much better at picking up colour in low light than the human eye as anyone who recently saw and photographed the northern lights probably noticed.

Anyway the subject of this image came up, Apologies for posting it again, I get people are probably sick of seeing it but I have added a bit of rain as some people asked for it. He explained that sodium lighting on a scale of colour gives a very high spike in the yellow range and doesn’t output any other colours. For this image to have the colours it does it would need a white light source, I cant say its the moon because its raining! It actually does have a white light source as I have a string of dim-able LEDs on the wall of the shed that I use to infill my night pictures. He very obviously knew exactly what he was on about! People may have noticed that at night we sometimes see in black and white. It was something I was already aware about on a very basic level. Cameras are much better at picking up colour in low light than the human eye as anyone who recently saw and photographed the northern lights probably noticed.

So I could say that the above image has a certain degree of artistic licence to it. Or at least I could if it was deliberate but the reality is it wasn’t. I hate it when people throw the term artistic licence around to justify missing something or some sort of mistake after its been pointed out. It’s OK to miss things, just don’t try and claim it was deliberate after the event.

So by taking all of the colour out except yellow (and putting some back in for the lorry lights and inside the phone box) we have an image that more accurately depicts what you would see if you were really standing on a rain sodden bridge in the Black Country at the end of the 1950’s. Two questions now though, The first is which of the two is actually the more pleasing, or nicer image? and the second is anyone actually bothered?

So by taking all of the colour out except yellow (and putting some back in for the lorry lights and inside the phone box) we have an image that more accurately depicts what you would see if you were really standing on a rain sodden bridge in the Black Country at the end of the 1950’s. Two questions now though, The first is which of the two is actually the more pleasing, or nicer image? and the second is anyone actually bothered?

3F and using a Brassmasters Easychas conventionally. Part 2

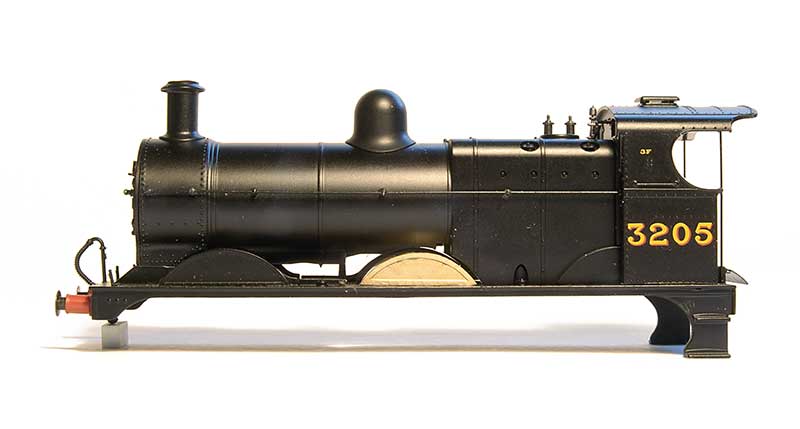

Much as I quite liked the accidental JPS tribute look of my 3F (Fans of retro Formula 1 will know what I mean) My 3f has now been painted and weathered.

I found this image of 43687 at New Street on station pilot duties around 1957. The loco was allocated to Bournville shed at the time so it seemed suitable to me. Image ©John Turner 53A Models of Hull Collection and used with his kind permission.

I found this image of 43687 at New Street on station pilot duties around 1957. The loco was allocated to Bournville shed at the time so it seemed suitable to me. Image ©John Turner 53A Models of Hull Collection and used with his kind permission.

Below a few images of the finished model.

Just waiting for a Modelu crew to arrive. Does anyone know how the cab rain sheets were attached to the tender on these locos? Ive found several images of them with the sheets stored on the edge of the cab roof but none with them in use. I guess back in the day people didn’t go out to take photos of mundane freight locos if it was raining!

3F and using a Brassmasters Easychas conventionally.

Ive always quite liked the Midland 3f tender locos. They seem to be quite nicely proportioned, more so than the 4F’s that looked kind of tall and somewhat top heavy. A while ago in quick succession I picked up a Bachmann body followed soon after by a tender body and a Brassmasters Easychas for it. In the last week or so Ive decided to get some sort of progress on it.

So starting with the tender. I never had the Bachmann chassis and if its anything like most RTR tender chassis it will no doubt have all been a bit flat and kinda naff. Brassmasters do a detailing kit to replace the tender chassis completely so I used that. This is just built as per their instructions.

So starting with the tender. I never had the Bachmann chassis and if its anything like most RTR tender chassis it will no doubt have all been a bit flat and kinda naff. Brassmasters do a detailing kit to replace the tender chassis completely so I used that. This is just built as per their instructions.

The rear end. Buffers are from Lanarkshire models as is the vac pipe. I think I’ll replace the lamp irons too.

The rear end. Buffers are from Lanarkshire models as is the vac pipe. I think I’ll replace the lamp irons too.

On to the loco. If I had the original chassis then based on the 1F I did I’m confident you could have something up and running in a somewhat leisurely afternoon. If you use the Bachmann coupling rods and brakes you might not even need to fire up the soldering iron! However as I didn’t have the Bachmann chassis I decided to build the chassis up as a more conventional one by adding spacers left over from a High Level Models Jinty chassis kit. As the easychas caters for EM and p4 the EM spacers are perfect. If you don’t have any leftover Jinty bits though Alan Gibson do a neat little etch of spacers.

Before I show you the chassis though some decisions need to be made. The splashers suffer from the usual RTR problem of being too big. Brassmasters do a separate etch for ones that are the right size. The above image shows a comparison so you can decide if it bothers you or not.

Before I show you the chassis though some decisions need to be made. The splashers suffer from the usual RTR problem of being too big. Brassmasters do a separate etch for ones that are the right size. The above image shows a comparison so you can decide if it bothers you or not.

As you can probably guess it bothered me so they were all replaced. The original footplate has a solid floor back to the front of the chassis casting so I cut that out. The new reversing lever is part of the chassis kit and the boxes on the side of the cabs have been thinned down by 2mm as per the instructions.

As you can probably guess it bothered me so they were all replaced. The original footplate has a solid floor back to the front of the chassis casting so I cut that out. The new reversing lever is part of the chassis kit and the boxes on the side of the cabs have been thinned down by 2mm as per the instructions.

All this means that a little bit of rectification is needed on the body as it had recesses in the boiler for the original splashers that are no longer needed. I believe the Bachmann chassis block comes quite far forward so the base of the boiler was put back in using layers of thin plasticard. Theres not really much else to do to the body other than this.

All this means that a little bit of rectification is needed on the body as it had recesses in the boiler for the original splashers that are no longer needed. I believe the Bachmann chassis block comes quite far forward so the base of the boiler was put back in using layers of thin plasticard. Theres not really much else to do to the body other than this.

Back to the chassis then – with the inside motion kit from the 4f – You didn’t expect me to leave a gaping hole did you? The gearbox is a high level loadhauler+

Back to the chassis then – with the inside motion kit from the 4f – You didn’t expect me to leave a gaping hole did you? The gearbox is a high level loadhauler+

How the loco looks mocked up. I will leave the sandpipes until the very end as they will trap the centre wheels in place.

Going over old ground

Ive recently been doing a few revisions on the layout.

The first was prompted by a failure. It had always irked me a little that the above lamp was a little bit crude and the top wasn’t really the distinctive shape the lights at Round Oak had. Being at the back in a dark corner it wasn’t noticeable enough to invest any time into. However when it recently failed why not kill two birds with one stone?

The first was prompted by a failure. It had always irked me a little that the above lamp was a little bit crude and the top wasn’t really the distinctive shape the lights at Round Oak had. Being at the back in a dark corner it wasn’t noticeable enough to invest any time into. However when it recently failed why not kill two birds with one stone?  So after a bit of tweaking I’m much happier with it now.

So after a bit of tweaking I’m much happier with it now.

Ground Signals. I originally used the MSE kits but I had found a few drawbacks. First thing was A few had took some knocks while cleaning the track. As they use a whitemetal casting for the main body and legs they really didn’t like this at all and were starting to look a bit bent and battered. Secondly as I had fitted lights there wasn’t a lot of room to work and I had just drilled out the lamp housing and shoved a nano LED in there with slightly mixed results.

Ground Signals. I originally used the MSE kits but I had found a few drawbacks. First thing was A few had took some knocks while cleaning the track. As they use a whitemetal casting for the main body and legs they really didn’t like this at all and were starting to look a bit bent and battered. Secondly as I had fitted lights there wasn’t a lot of room to work and I had just drilled out the lamp housing and shoved a nano LED in there with slightly mixed results.

One consequence of this wass more light bled out of the bottom than through the signal despite various attempts to fill the hole

One consequence of this wass more light bled out of the bottom than through the signal despite various attempts to fill the hole

So step in the Palatine models etched kits as a replacement. These are hopefully stronger and being an etch theres more room to position the LED in a better controlled way. I say more room but in 4mm scale ground signals are tiny but because of that even a slight gain is a big help. I modified the kits a little to make them work and drilled a couple of holes for the lights. Results are below

On the subject of signals Ive been playing around with resistors again to try to get the lamps a bit closer to how the real thing looked and less like a modern colour light. I think I’m there now.

Up on the road Ive added a few telegraph poles meaning I think I can call this area finished now.

A revisit to my classic (or is that cliché?) scene. This time a wider verson.

A revisit to my classic (or is that cliché?) scene. This time a wider verson.

Back to wagons – and a correction.

A while ago I did a batch of shock opens including an attempt at an ex-LMS diagram 1983 variant. Justin of Rumney Models noticed that I had used the same ends as the BR version with inset corrugations while the LMS wagon has corrugations that stick out. Something I had completely failed to notice myself. So that wagon had its top lip removed and renumbered back to a BR one. A new kit was brought (well a few actually – saves on postage!) and a second attempt made using cut down spare ends from a Parkside 12t van kit. The BR version is at the back. Theres a few other differences too like the bang plates for the doors, the shape of the panelling on the ends and the braces under the door.

The finished wagon in the company of yet another D2150 13t open.

The finished wagon in the company of yet another D2150 13t open.

The BR wagon has had a Rumney models sheet rail added and been mated with a clasp brake chassis to produce a D1/040 variant. Buffers are from Lanarkshire Models.

The BR wagon has had a Rumney models sheet rail added and been mated with a clasp brake chassis to produce a D1/040 variant. Buffers are from Lanarkshire Models.

Moving on to a couple of hoppers.  First up the Accurascale 24.5t hopper which i picked up cheaply from a private sale on Western Thunder. It came in brown livery and with a certificate saying it was a limited edition number 061 of 500. If this sort of thing matters to you and you have one you will be pleased to know that your model is now even more limited being 1 of 499 (You’re welcome!). It was separated into its component parts (a process that had already started in the box) and the body resprayed. These are not a straight drop in wheels job as the axles used are a little short and theres a boss on the back of the W-iron, much like Lima was doing 40+ years ago. Its not a huge problem though as a few turns of a bearing cutter (I use Ed’s tool) and a little bit of thinning the boss down and off you go. I also cut off the NM pockets.

First up the Accurascale 24.5t hopper which i picked up cheaply from a private sale on Western Thunder. It came in brown livery and with a certificate saying it was a limited edition number 061 of 500. If this sort of thing matters to you and you have one you will be pleased to know that your model is now even more limited being 1 of 499 (You’re welcome!). It was separated into its component parts (a process that had already started in the box) and the body resprayed. These are not a straight drop in wheels job as the axles used are a little short and theres a boss on the back of the W-iron, much like Lima was doing 40+ years ago. Its not a huge problem though as a few turns of a bearing cutter (I use Ed’s tool) and a little bit of thinning the boss down and off you go. I also cut off the NM pockets.

What is a little bit more of an issue is it doesn’t weigh anything, just 21 grammes out of the box. Obviously if you plan to run your wagons loaded no problem but if you want them empty (as did ) then a little bit of trickery is required.

My solution was to make new lower sides from 1mm lead. This brings the wagon up to 50 grammes. If you would like to follow suit I drew up a little cutting template which you can download from here

My solution was to make new lower sides from 1mm lead. This brings the wagon up to 50 grammes. If you would like to follow suit I drew up a little cutting template which you can download from here

Another parkside 21 tonner based on a picture that came up on my facebook feed. (some of the wagons in the post are waiting a delivery of couplings you may notice). Theres often a discussion when these kits crop up that they are difficult to build but they really aren’t. The trick is to assemble a side and end as 2 pairs on a piece of glass with a cutting matt to ensure they are square, let these set fully before assembling the rest of the wagon and theres no problems Any slight gaps between the panels can be filled from the inside using Mr Surfacer 1000 liquid filler.

Another parkside 21 tonner based on a picture that came up on my facebook feed. (some of the wagons in the post are waiting a delivery of couplings you may notice). Theres often a discussion when these kits crop up that they are difficult to build but they really aren’t. The trick is to assemble a side and end as 2 pairs on a piece of glass with a cutting matt to ensure they are square, let these set fully before assembling the rest of the wagon and theres no problems Any slight gaps between the panels can be filled from the inside using Mr Surfacer 1000 liquid filler.

Now a few oddballs – this is an ex L&Y diagram 81 loco coal wagon from the old MAJ models kit. The kit is supplied with a wooden chassis which is correct for the earlier wagons but i wanted the later one so only used the body. The brake gear on these were a little weird to say the least

Now a few oddballs – this is an ex L&Y diagram 81 loco coal wagon from the old MAJ models kit. The kit is supplied with a wooden chassis which is correct for the earlier wagons but i wanted the later one so only used the body. The brake gear on these were a little weird to say the least

The plan is to have a short train of condemned wagons that is delivered to the yard as a trip working from Bescot. These are then to be collected by one of the Round Oak locos to be taken away for scrapping and the metal bits melted down in the furnaces. This is basically what happened and quite a few locos met their fate this way in real life. Unlike some of the more famous railway scrap yards stuff didn’t hand around for long so nothing from my scrap train will have any hope of reprieve sadly. The condemned markings are from Railtec,